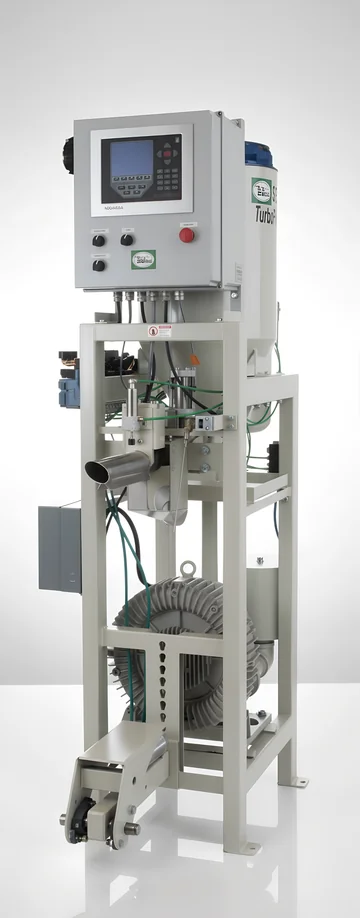

Series 330E - Bulk Bag Equipment

- High-volume FIBC filling

- Conveyor integration

- Adjustable speed control

UL Certified Industrial Control Panel Shop

NTEP Conformance Standards

Industrial bulk bag filler hoppers designed for efficient packaging of powders, granules, and fine materials. Our FIBC filling systems feature adjustable height capabilities, dust control options, and automated weighing for precise material handling across food, chemical, agriculture, and mining industries.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 7 results

What types of materials can be filled with bulk bag fillers?

Powders, granules, pellets, resins, and fine materials including cement, flour, pigments, chemicals, and food ingredients.

What power requirements are needed for bulk bag filling equipment?

Can bulk bag fillers handle different bag sizes?

What automation levels are available for bulk bag fillers?

Do you offer dust control options for fine powders?

What weighing accuracy can be expected from these systems?

Can bulk bag fillers be integrated into existing production lines?

Talk to our experts for custom solutions and tailored guidance.

Bulk bag filling systems for food ingredients, flour, sugar, and dairy powders with sanitary design.

FIBC filling equipment for chemical powders, pigments, and hazardous materials with safety controls.

Heavy-duty bulk bag fillers for fertilizers, seeds, minerals, and aggregate materials handling.

Specialized FIBC filling systems for plastic pellets, resins, and polymer materials with precise control.

Talk to our experts for custom solutions and tailored guidance.

Family-owned business with certified UL control panel shop providing custom design capabilities for unique bulk packaging requirements.

Over 15 years specializing in dry bulk material filling with installations across US, Canada, Mexico, South America, and Middle East.

Small company agility to meet tight deadlines while maintaining capability to handle large-scale industrial automation projects.

Connect with our technical team for custom FIBC filler recommendations. Expect prompt response from our certified engineers.

For immediate assistance, feel free to give us a direct call at (620) 421-9800 You can also send us a quick email at sales@hhdesignmfg.com

For immediate assistance, feel free to give us a direct call at (620) 421-9800 You can also send us a quick email at sales@hhdesignmfg.com