Dust piles near the transfer zone. Cartons slip on a shallow incline. Operators tap the belt because products stall at every merge. Why does your line stall the moment products move from loading to bagging?

Belts fail quietly. Conveyor belts for processing packaging & material handling applications are engineered surfaces that move products at controlled speed, protect spacing, prevent slip, and manage load through every stage of the line. When the belt type does not match the product, the system creates drag, jams, wear, or inconsistent handoff. In this blog, we will break down how to choose the right belt based on product behavior, throughput demands, and real operating conditions.

Engineering Notes on Belt Types You Should Not Ignore

Flat top belts are stability tools, not “general purpose.” They protect spacing on trays and cartons, but fail the moment moisture or incline forces lower friction. If operators keep nudging products uphill, the belt type is wrong, not the speed.

Curved belts exist to eliminate transfer points, not to save floor space. They work only when radius, load, and rail pressure match. If heavy crates skid outward or labels scuff, the curve geometry is mismatched, not the motor.

Flush-grid belts are drainage mechanisms, not airflow accessories. They prevent pooling, cooling issues, and washdown residue. They only work when sanitation clearance, pitch, and loading direction prevent packaging from deforming into the openings.

Friction-top belts replace gravity compensation, not operator tapping. When bottles slip on inclines or pouches slide back at elevation, you do not tighten the belt first. You pick a belt designed to grip under acceleration and braking.

Roller-top belts reduce force, not carry delicate goods. They prevent carton burn in accumulation zones, but destroy fragile items when roller gaps or roller diameter do not match the footprint. Calibration matters more than horsepower.

How to Choose Conveyor Belts for Processing Packaging & Material Handling Applications

Conveyor belt selection starts with the product, not the frame. Every material behaves differently in motion, so you match belt geometry, surface profile, and perforation to real behavior, not catalog descriptions. You balance flow stability, sanitation access, maintenance effort, and target throughput.

Evaluate the material itself:

Size and shape affect movement. Smaller packs slip on smooth surfaces. Larger trays drag on textured belts.

Moisture alters friction. Cold packaging sweats. Sticky powders cling.

Weight influences fatigue and tension cycles.

Packaging type dictates grip.

Inclines and declines increase loading force and spacing variability.

Gravity-fed entry behaves differently from indexed loading.

Evaluate the environment around the material:

Seafood, produce, or wet products require drainage and washdown.

Warm bakery goods release condensation that increases belt stickiness.

Abrasive minerals or bulk powders wear belt edges and rollers.

Temperature swings affect module stiffness and hinge flexibility.

Evaluate safety and serviceability:

Operators should reach belts without awkward bending.

Cleaning should not depend on full disassembly every shift.

Proper selection protects staff and prevents unpredictable line behavior.

1. Belt Surface Design

Belt surface is the interface between motion and product, and it controls friction, drainage, heat transfer, and how loads settle under acceleration. The wrong texture causes slip, bounce, or micro jams long before throughput visibly drops, so you are not choosing aesthetics; you are determining how your line behaves.

Flat top belts support stable products like cartons or trays, while grip top belts hold bottles, pouches, or lightweight boxes on inclines and declines. Flush grid or perforated belts provide airflow and drainage for wet, chilled, or sanitized environments.

Surface design prevents common pathologies:

Staling when liquids pool under the belt or packaging sweats

Slipping when the incline's friction is too low

Product bounces when the perforation spacing is mismatched with the item size

Debris buildup occurs when flat surfaces accumulate crumbs, dust, or pulp

You choose a surface to eliminate a failure mode. If you see operators tapping the belt, if cartons drift toward edges, or if fine powder accumulates along ribs, you do not have a surface issue to ignore. You have a mismatch between product physics and belt behavior.

2. Belt Pitch, Transfer, and Part Stability

Pitch determines how smoothly products hand off between conveyors. A smaller pitch reduces the gap at the transfer point. This stabilizes light items and prevents wedging or falling into roller gaps. Large pitch belts can carry heavier items, but the handoff will be aggressive and unsuitable for smaller packages.

Below are common use cases matched to pitch configurations:

Tight transfer belts: Suitable for snack foods, confectionery, blister packs, and small pharma packages. Items pass from belt to belt with minimal drop. This reduces edge bruising or label abrasion.

Small to medium pitch modular belts: Used in general packaging lines where items have a flat base and moderate weight. They balance stability and durability across multiple zones.

Large pitch modular belts: Required for crates, pallets, automotive parts, stamped metal, and heavy assemblies. They carry mass predictably at slow speeds. Transfer points must be designed with supporting rollers or plates to avoid collisions.

Stable transfer is not about moving items forward. It is about handing momentum from one surface to another without forcing the product to react. When pitch is mismatched, jams start at transitions and expand into full-line stoppages.

3. Belt Load Capacity and Duty Classification

Conveyor failures start when designs consider maximum load instead of operational cycles, so a belt that lifts a crate twice an hour may fail when the same crate arrives every 20 seconds. Packaging lines apply distributed pressure while bulk material lines concentrate mass.

Standard duty belts deliver consistent motion for light packaging or bottled beverage lines, but heavy-duty belts are built for repeated stress, thermal expansion, and impact. Reinforced hinges, thicker modules, and tighter roller spacing prevent structural fatigue that destroys lighter belts.

A summary of load considerations:

Frame rigidity: A weak frame flexes under load. Flexing multiplies pitch wear, causing premature belt failure.

Fatigue and wear: Repeated loads cause module cracking or hinge expansion. The belt stretches unevenly and drifts.

Roller spacing and support: Too much gap means bending under every crate or pallet. You get permanent belt deformation.

You classify belts by predictable stress, not marketing labels. When heavy products stall at an incline or when pallet edges cut into modules, the line is not underpowered. It is under-engineered for the conditions it runs every day.

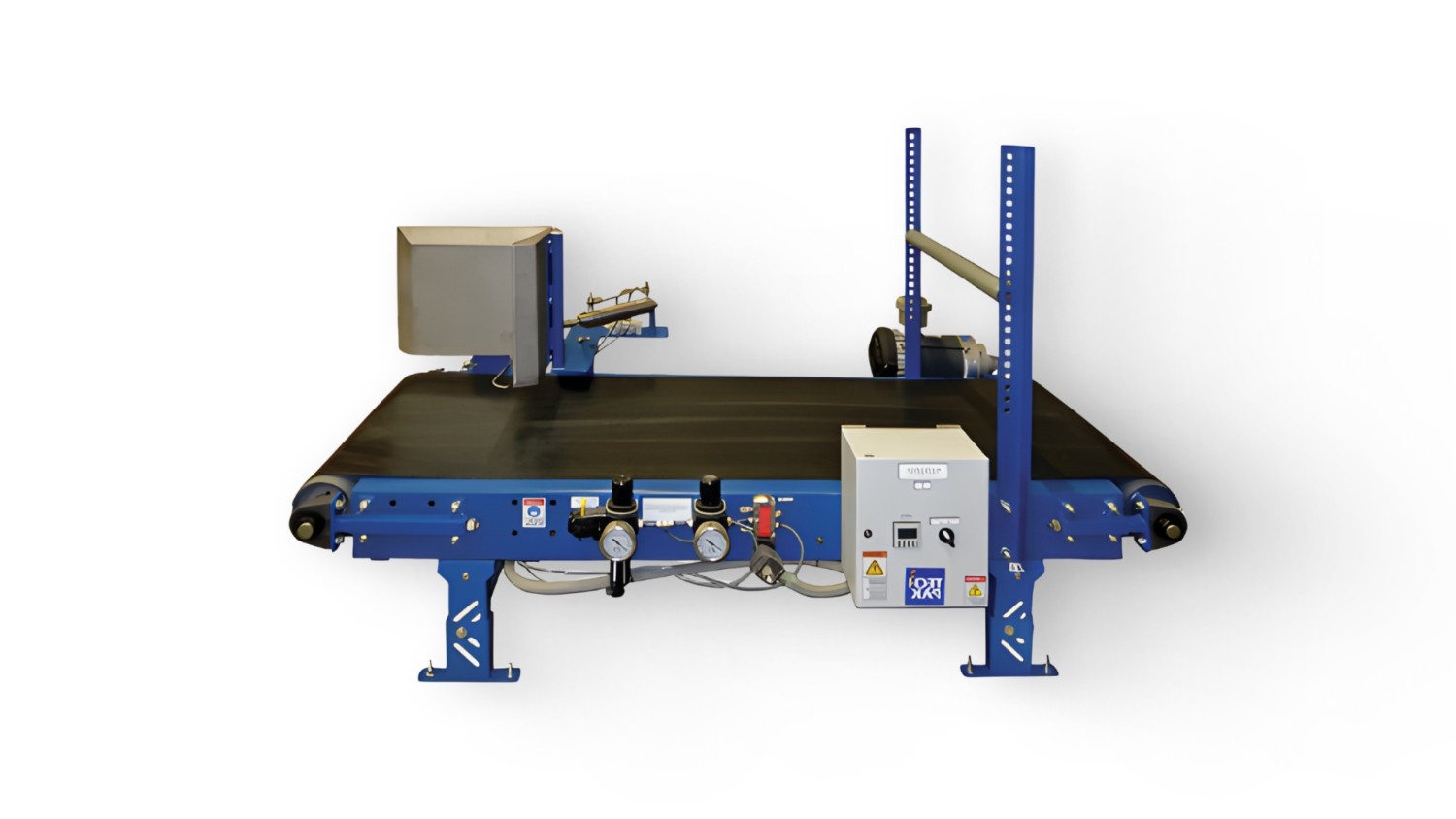

Learn how Series 33PT Conveyors handles pallet flipping and orientation without manual repositioning. Compare rotation type, safety interlocks, and control panel operation to match your handling requirements.

If surface, pitch, or load seems abstract, the belt types below will make it painfully clear. These are the models that stop the stalls you fight every shift.

8 Conveyor Belts for Processing Packaging & Material Handling Applications

Different conveyor belts solve different movement problems. You do not pick a belt because it is common in your industry. You pick it because it behaves properly under your load, spacing pattern, and environmental conditions. Each belt type below addresses a specific failure mode. If a belt cannot manage drainage, grip, transfer clearance, or weight cycles, it will cause stoppages even if the rest of the conveyor works perfectly.

1. Flat Top Modular Belts: Series 150

Flat top modules provide a continuous surface for products with stable bases. They are used in packaging lines, bottling, food processing, and general carton transport because they prevent edge pressure and maintain spacing.

Where they work well:

Horizontal and low-angle conveyors

Cartons, trays, stable rigid packaging

Assembly lines that require consistent support

Where they fail or cause friction:

Wet inclines or areas where moisture reduces friction

Lines with inconsistent product geometry

Zones where liquids or crumbs accumulate beneath the belt

2. Curved Flat Top Belts (90° or 180°): Series 151C

Curved modular belts redirect product flow without creating a transfer point. They maintain line continuity when the layout cannot accommodate straight runs.

Appropriate use cases:

Space-restricted packaging, pharma, and distribution lines

Controlled directional changes without secondary conveyors

Single-belt layouts that reduce drop zones

Design limitations:

Large, heavy items on tight radii

Overloaded runs where centrifugal force pushes products outward

Curves with rail pressure that scuff labels or deform trays

3. Flush Grid or Perforated Surface Belts: Series 152

Flush grid belts allow liquid and airflow to pass through the belt. They are chosen for sanitary areas where washing, cooling, draining, or drying occurs.

Ideal applications:

Produce, seafood, bakery cooling

Washdown food environments

Wet or moisture-heavy conveyors

Critical cautions:

Packaging that spans holes or ribs may deform

Insufficient sanitation clearance leads to residue buildup

Poor drainage angles force operators to scrape the belt

4. Friction Top Belts: Series 153

Friction top belts use textured surfaces to prevent product sliding. They are used where gravity works against the conveyor, especially on incline or decline paths.

Best suited for:

Beverage cans and bottles

Pouches, blister packs, lightweight cartons

Incline/decline zones that cannot rely on speed or side rails alone

Failure conditions:

Under-tensioned belts slipping under light loads

Over-tensioned belts causing premature edge wear

Abrasive packaging that chews through surface texture

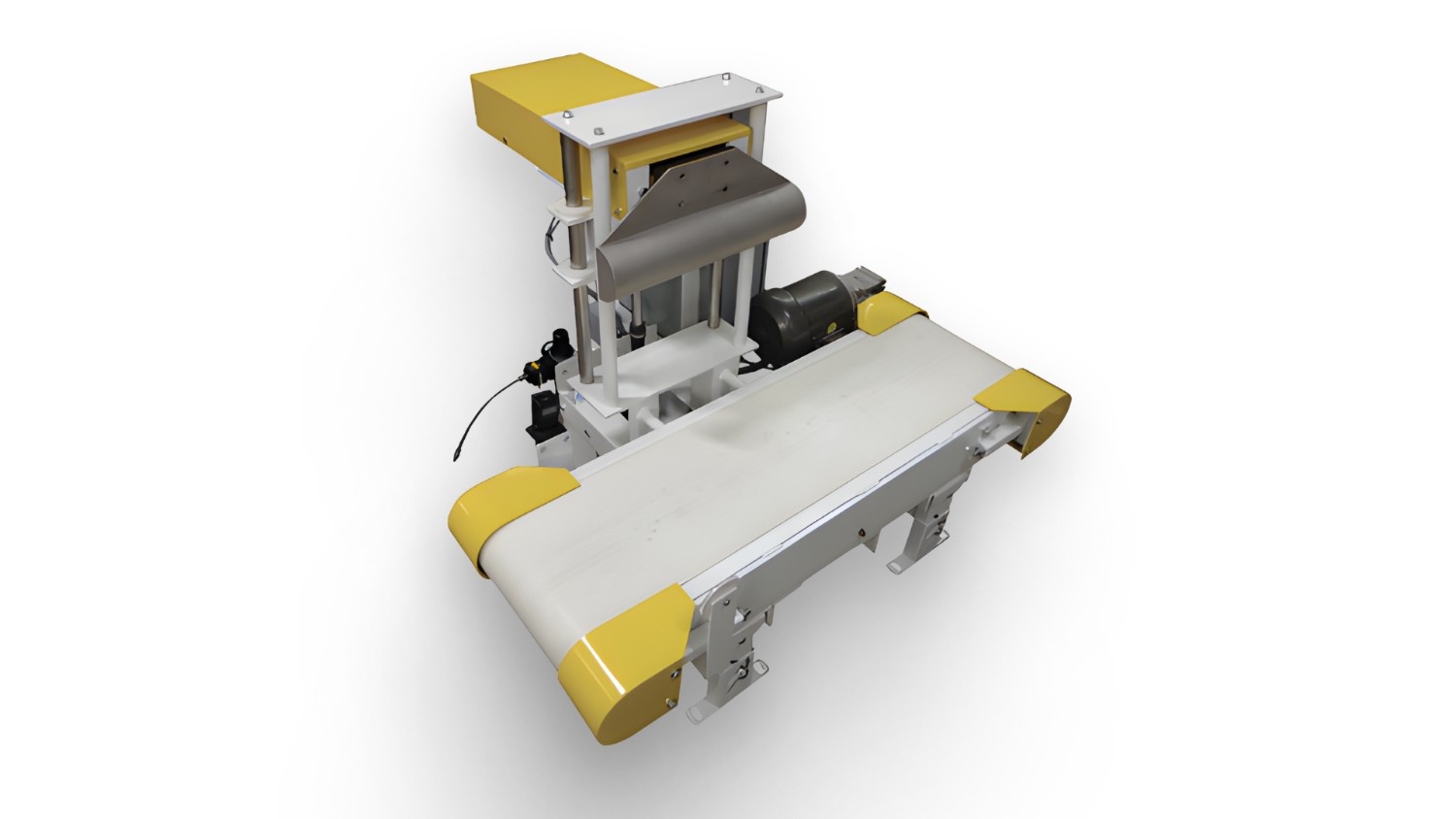

5. Roller Top / Low Back Pressure Belts: Series 154

Roller-top belts move product on rollers while the belt travels beneath. They reduce contact force during accumulation, merging, or diverting.

Where they perform well:

Sorting lines

Packaging accumulation buffers

High-throughput logistics where dwell time is frequent

Where they cause issues:

Fragile goods spanning roller gaps

Lines where rollers are poorly cleaned or blocked with debris

Systems relying on roller top to compensate for poor layout geometry

Series 250 Conveyors handle tight transfers while Series 151C Conveyors maintain smooth 90° and 180° orientation changes across your line. Upgrade your movement now.

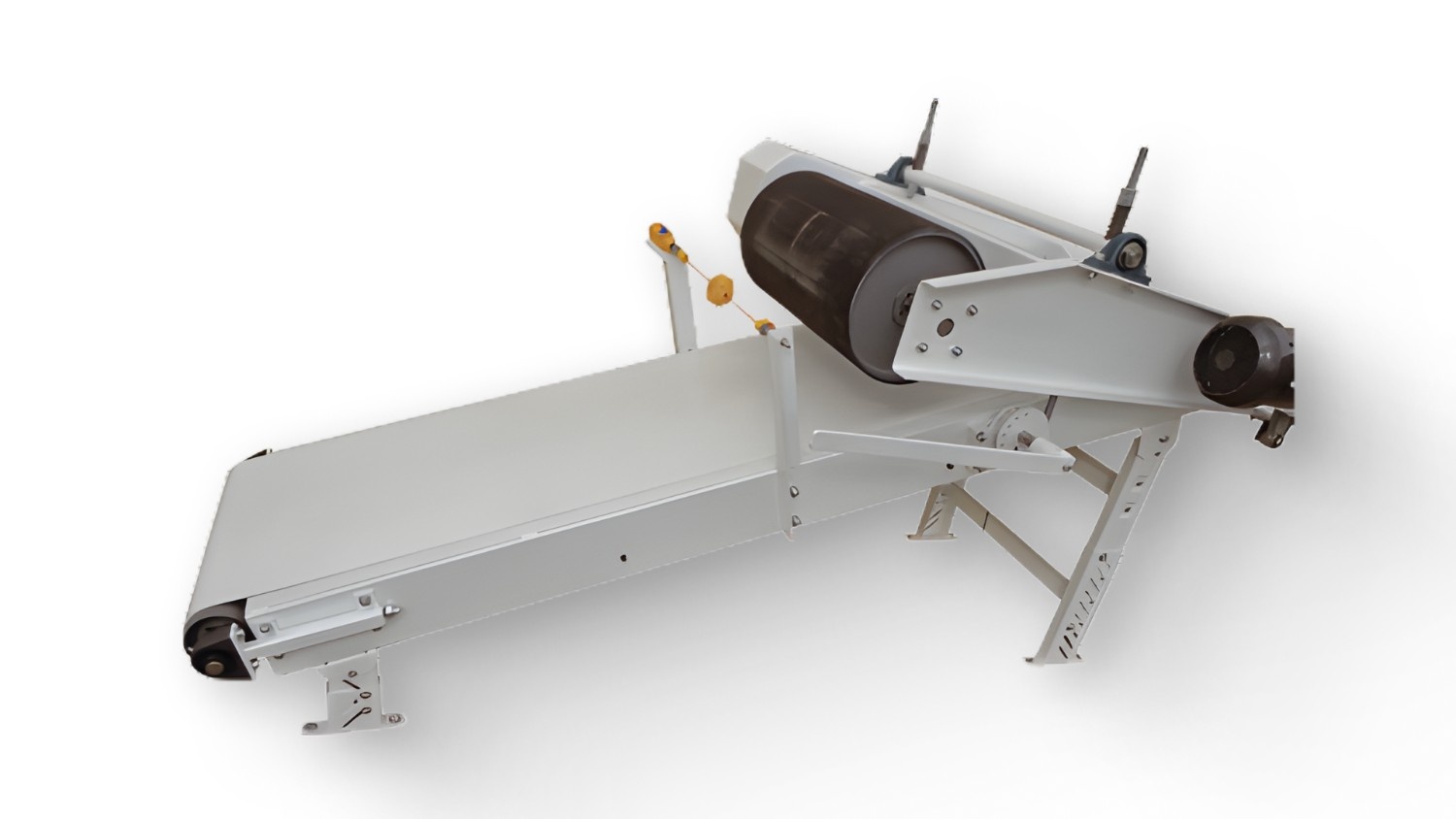

6. Raised Rib / Grip Top Belts: Series 155

Raised rib belts use elevated profiles to stabilize slippery or curved items. They secure trays, frozen goods, and baked products on incline routes.

Key use scenarios:

Products with minimal base contact

Steep incline transport

Lines with repetitive acceleration zones

Common failure symptoms:

Rib misalignment grinding belt edges

Entry/exit planes that strike ribs instead of guiding them

Packaging catching between ribs due to incorrect pitch

7. Heavy-Duty Modular Belts: Series 156

Heavy-duty belts are designed for repeated force, high mass, and shock impact. They handle automotive parts, metal stampings, recycling, and heavy bulk.

Where they are appropriate:

Large component handling

Bulk material discharge and loading

High-load areas with constant contact stress

Misapplication problems:

Frames that flex under weight

Roller spacing too wide for concentrated loads

Shock zones without protective bracing

8. Tight Transfer / Small Pitch Belts: Series 250

Small pitch belts minimize the gap at transitions. They are used to move small, delicate items between conveyor zones with minimal drop.

Where they excel:

Snack food, confectionery, pharma items

Small part transfers or blister packs

Light accumulation requiring gentle handling

Where they fail:

Heavy or oversized products bridging modules

Transfer plates missing or misaligned

Upstream feed angles that generate tumble instead of glide

Belt choice solves half the problem. The other half is having a manufacturer who understands that behavior on the floor, not just on a spec sheet.

How Does H&H Design & Manufacturing Build Custom Conveyor Solutions Around Material Behavior?

You do not fix conveyor problems by changing motors or belts at random. You fix them by engineering around the material itself. H&H Design & Manufacturing builds conveyors this way. They start with the product, study how it behaves in motion, and design the belt, frame, controls, and support so the material flows without operator intervention. There is no catalog-first approach. There is material-first engineering.

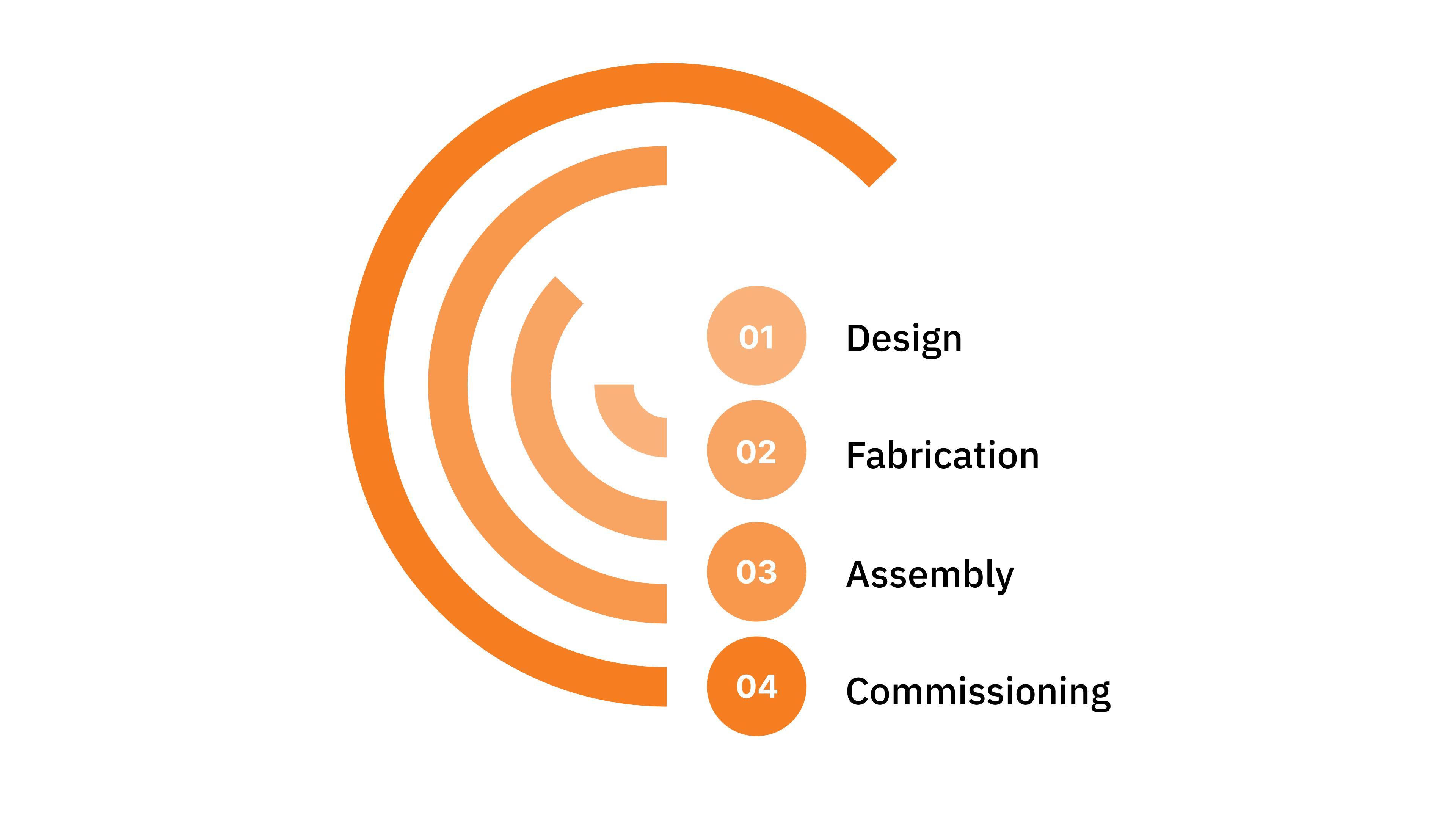

H&H Design & Manufacturing is a family-owned company that controls the entire production lifecycle. You speak to the people who design the system, not a distributor or middle layer. Their team starts with requirements, fabricates the structure in-house, assembles the equipment, and commissions it on site. You get one accountable group that knows the machine from its first weld to its first hour of runtime.

Below is the lifecycle approach that prevents blame loops and patchwork solutions:

Design: The engineering team studies product geometry, moisture, abrasion, and how the material loads into the conveyor. Belt type, pitch, roller spacing, and frame stiffness are selected from actual behavior, not assumptions.

Fabrication: Parts are built in-house so tolerances, welds, and supports match real stress conditions. This prevents structural flex that destroys belts under heavy or repetitive loads.

Assembly: Conveyors are aligned, tensioned, and tested as a system. Transfer plates, guards, and roller supports are fitted to match product flow paths.

Commissioning: H&H Design & Manufacturing calibrates the line on-site. They verify stability, drainage, grip, and spacing with your actual material, not a simulation.

They also bring historical experience in maintaining and upgrading Tech Packaging equipment. If you run legacy systems, they do not force replacements. They modify modules, reinforce frames, and tune the line until the output becomes predictable.

Explore more conveyor solutions engineered for real material behavior. See how belt type, geometry, and load handling change line performance.

Conclusion

The right conveyor belt solves problems before they reach operators. When the belt matches product behavior, you see fewer stalls, consistent flow, and safer handling. The line stops fighting itself, and maintenance becomes scheduled work, not emergency response. Conveyor belts for processing packaging, and material handling applications are not generic parts. They are engineered interfaces between your product and motion. Describe your material to H&H Design & Manufacturing will design the belt around it.

If you need a system that fits your material instead of forcing your material to fit the system, reach out to H&H Design & Manufacturing. Tell us what you run, how it moves, and where it fails.

FAQs

Q: What happens if a conveyor belt is sized correctly but the frame lacks rigidity?

A: A belt can track correctly during commissioning and still drift once the frame flexes under load. Structural movement changes roller alignment and pitch stress. You get belt creep, edge wear, and unpredictable handoffs even when the motor runs normally.

Q: Do curved conveyors reduce jams in tight spaces, or do they introduce new risks?

A: They reduce transfer-point jams because the product stays on a single belt through the corner. They also concentrate lateral force, so heavy items can slide outward when the curve radius, rail pressure, or speed is ignored.

Q: How do modular belts behave when handling mixed SKUs with different bases and weights?

A: Mixed SKUs destabilize when a single surface favors only one geometry. Lighter packs drift while heavier trays anchor, creating uneven lanes. You must tune surface friction, guide spacing, and pitch to the worst-performing product, not the average.

Q: Why do incline conveyors run fine during testing but fail once temperature changes in production?

A: Thermal shifts alter belt stiffness, hinge flexibility, and surface friction. Cold environments harden modules, changing how products settle and grip. Hot zones soften the belt, increasing sag and forcing operators to compensate with rails or manual taps.

Q: Can roller-top conveyors damage products even if they are rated for accumulation?

A: Accumulation ratings assume compatible footprint and roller gap spacing. If a product spans rollers unevenly, force transfers to the edges or corners. The conveyor works mechanically, but the product experiences localized crushing and deforming.

Q: How do you diagnose a belt that “runs perfectly” but still causes slow throughput losses?

A: Watch the transitions, not the motor. Micro stalls at bends, tiny edge drifts, or small bounce events compound into lost units per hour. Operators tapping products is a mechanical symptom, not a training issue.