Conveyor systems are now indispensable in modern manufacturing; global studies show they can boost material handling efficiency by 30–40%, dramatically reducing processing time compared to manual methods. For plant managers and engineers, knowing the different types of conveyor belts is critical, since the right belt directly affects uptime, throughput, safety, and operating cost.

As the backbone of automated bulk packaging lines, conveyor belts keep material moving consistently from one stage to the next. Yet challenges like inconsistent flow, manual bottlenecks, dust, and safety risks remain common across facilities.

In this article, we’ll break down the different types of conveyor belts and explain where each one is used in bulk material handling and packaging.

Key Highlights

Conveyor belts significantly boost material-handling efficiency and are essential for maintaining consistent product flow in automated packaging lines.

Each conveyor type, flat, troughed, incline, modular plastic, roller bed, and cleated, serves a specific handling requirement based on material behavior, layout, and throughput.

Correct conveyor selection depends on factors like material type, weight, dust control, speed demands, and integration with downstream equipment.

Conveyors improve line accuracy, reduce manual handling, increase throughput, and ensure smooth coordination between filling, sealing, and palletizing systems.

H&H Design Mfg offers engineered conveyor solutions tailored for sealing, conditioning, weighing, orientation, and high-speed transfer, enabling complete, efficient dry-bulk packaging lines.

What Is a Conveyor Belt System?

A conveyor belt system is a continuous, motor-driven mechanism designed to move materials from one stage of a process to the next. The moving belt, made from rubber, fabric, or modular plastic, creates a controlled, consistent flow through a production or packaging line.

Conveyor belts are widely used in bulk material handling because they can efficiently transport:

Powders (cement, flour, chemicals)

Granules (fertilizer, sugar, plastic resin)

Pellets (wood pellets, feed pellets)

Finished packaged goods (filled bags, boxes, cartons)

These systems deliver major operational advantages:

Eliminate manual lifting and reduce operator strain

Improve consistency in product flow between machines

Reduce downtime caused by uneven or delayed material movement

Enhance safety by minimizing human contact with heavy or hazardous materials

Conveyor belt systems are especially critical in automated bagging lines, where precise timing and uninterrupted flow are essential for accurate weighing, filling, sealing, and palletizing. A well-matched conveyor ensures the entire line functions as a smooth, coordinated system.

Different Types of Conveyor Belts Explained

Below are the primary conveyor belt types used in bulk material handling and packaging lines. Each section now includes added operational insights, design considerations, and practical selection guidance.

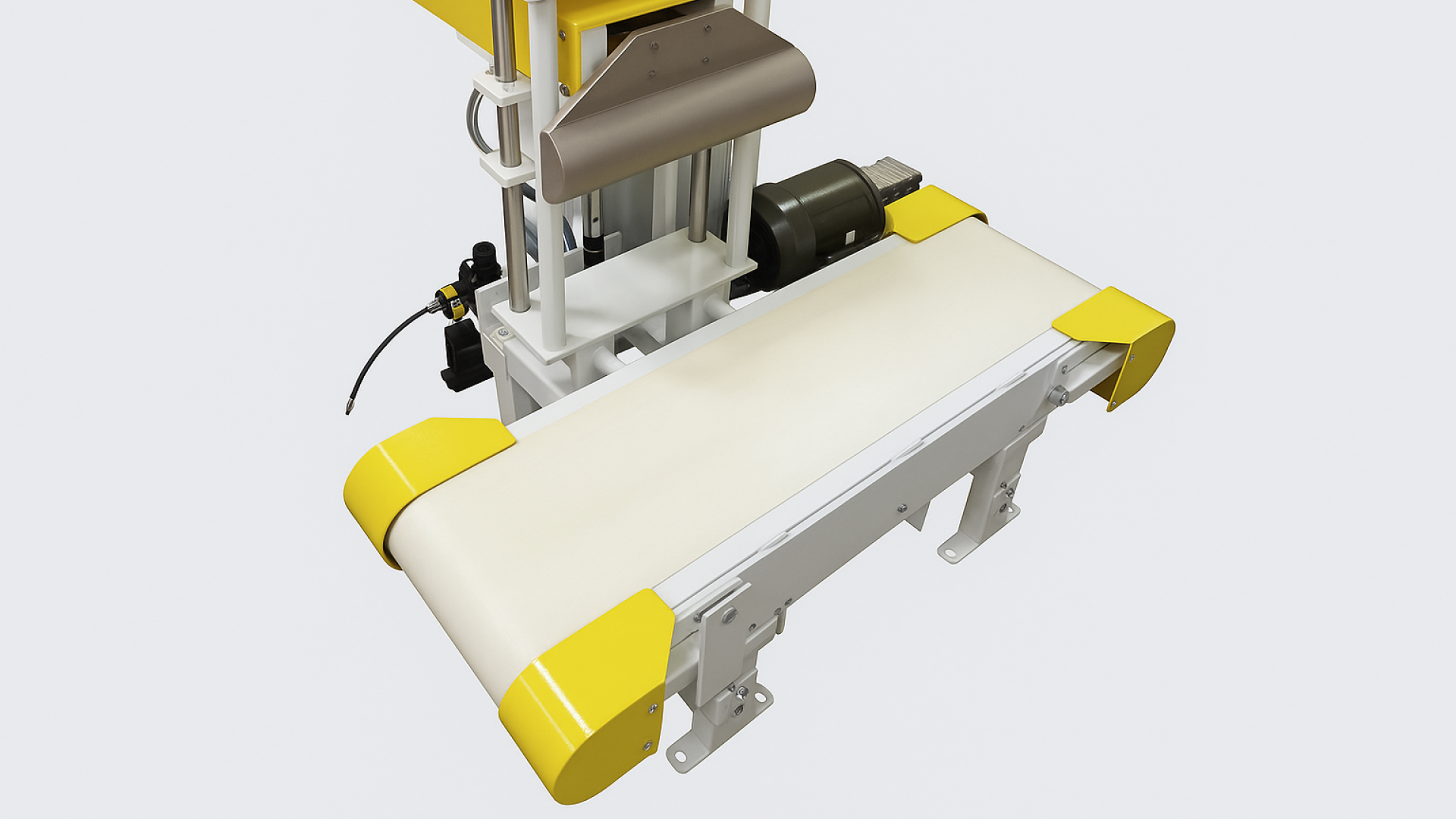

A. Flat Belt Conveyors

Flat belts are the most universal conveyor type because they offer consistent, controlled movement for a wide range of product shapes and weights.

Key advantages & design value:

Handles filled bags, cartons, pails, and bulk containers with stable support

Ideal downstream of weighers and bag fillers because they preserve bag shape and prevent tipping

Provides a smooth path for metal detectors, checkweighers, and sealing stations

Available in various belt materials: rubber, PVC, PU, and fire-resistant compounds for harsh environments

Can operate at adjustable speeds to match filler output and prevent line stalls

Where they shine: Food ingredients, fertilizers, animal feed, minerals, chemicals, and general industrial packaging.

From intake to final packaging, H&H Design Mfg’s Series 152–156 conveyors keep your line synchronized, stable, and production-ready

B. Troughed Belt Conveyors

Troughed belts cradle material, creating a natural channel that keeps loose product centered.

Why they matter in material handling:

Prevents spillage and reduces housekeeping, and especially valuable with dusty or high-flow materials

Supports higher throughput because material can be loaded deeper in the belt

Performs well even with uneven feeding or surges from upstream equipment

Low energy consumption compared to screw conveyors or pneumatic transfer

Best applications: Upstream feeding, transferring powders to hoppers, moving granules between processes, or bridging distances between equipment.

C. Incline & Decline Conveyors

Incline/decline conveyors solve elevation challenges without the need for complex lifts or manual handling.

Operational benefits:

Safely moves bags or materials to mezzanines, palletizing decks, or processing floors

Reduces footprint by using vertical space, critical in compact or retrofit facilities

Can be fitted with rough-top or high-friction belts to prevent slipping

Ideal when integrating robotics, since a consistent height is needed for pick points

Engineering note: The steeper the incline, the more likely you need cleats, sidewalls, or a high-grip belt.

D. Modular Plastic Belt Conveyors

These conveyors excel in environments where hygiene, durability, or exposure to moisture is a concern.

Key advantages:

Withstands washdown, caustic cleaners, and high-temperature sanitation

Sections are replaceable, minimizing downtime and total cost of ownership

Open-hinge designs allow water and debris to fall through, preventing buildup

Excellent for indexing, turning, or directional changes due to positive sprocket drive

Most common in: Food processing, specialty chemical packaging, corrosive environments, and anywhere belt life is a concern.

E. Roller Bed or Roller Top Conveyors

Roller-based conveyors reduce friction and are ideal for heavy or bulky loads.

Why do operations choose them:

Requires less horsepower to move large or long products

Excellent for pallets, large bags (25–50 kg), drums, and bulky boxes

Gravity roller options offer low-cost movement where power isn’t required

Easy to integrate into sorting, accumulation, or manual handling zones

Commonly seen in: Distribution centers, warehouse packaging lines, and high-throughput palletizing areas.

F. Cleated Belt Conveyors

Cleats act like small paddles, giving products traction and preventing rollback on steeper inclines.

When they’re essential:

Moving powders or pellets up steep angles toward hoppers or baggers

Keeping small or slippery materials spaced during movement

Maintaining metered flow into downstream equipment

Preventing product pile-ups or inconsistencies caused by incline slippage

Cleat types:

Straight cleats (general use)

Scoop cleats (for lightweight or loose materials)

L-shaped cleats (for maintaining spacing and orientation)

G. Magnetic or Metal Belt Conveyors (High-Level Mention)

These specialty conveyors use magnets or metal slats to handle products that standard belts cannot.

Key uses:

Moving ferrous metal parts, scrap, or tools

Protecting equipment by separating metallic contaminants

Withstanding high temperatures where rubber or plastic belts fail

While not typically part of dry bulk packaging lines, they are important in facilities that combine machining or recycling operations with packaging.

H. Custom or Application-Specific Conveyors

These conveyors solve specialized flow challenges and link individual machines into a seamless automated line.

Examples & their value:

Bag turn conveyors: Rotate bags for print alignment or proper sealer orientation

Reject conveyors: Remove out-of-spec bags based on weight, seal quality, or metal detection

Accumulation conveyors: Create controlled buffers to prevent bottlenecks when filler and palletizer speeds differ

Integration conveyors: Ensure smooth transfer from filler → sealer → checkweigher → palletizer, matching machine speeds and spacing

H&H Design Mfg’s custom conveyors turn complex packaging challenges into smooth, efficient, operator-friendly production flow

How to Choose the Right Conveyor Belt?

Choosing the right conveyor belt is essential for maintaining smooth material flow, protecting equipment, and ensuring the entire packaging line performs reliably.

Key factors:

1. Material Type

Choose the belt based on how the product behaves. Powders need dust-controlled or troughed belts to prevent spillage. Granules and pellets run well on flat or troughed belts. Fragile materials require smooth, gentle handling, while abrasive products need heavy-duty, wear-resistant belts for long service life.

2. Bag or Container Weight

Weight determines belt strength and drive requirements. Light bags work well on standard flat belts, while heavier 25–50 kg bags move more efficiently on roller bed conveyors. Very heavy or bulky loads may require reinforced belts or powered roller systems for stable, low-resistance transport.

3. Required Throughput (Bags per Minute)

Higher speeds demand better belt tracking, tensioning, and smooth transfers. Standard belts handle moderate speeds, but high-throughput lines benefit from modular plastic belts or reinforced flat belts that maintain stability and reduce vibration-related rejects.

4. Plant Layout & Elevation Changes

Your layout dictates conveyor geometry. Flat or roller beds are ideal for long horizontal runs. Incline/decline conveyors maximize vertical space in compact plants, while cleated belts are needed for steep inclines to prevent rollback.

5. Dust Control Requirements

Dusty or aerated materials require belts that control spillage and help maintain a clean environment. Troughed belts keep fine material centered, while modular plastic belts suit sanitation-focused plants needing frequent washdown. Enclosed or slower belts may be required for highly airborne materials.

6. Integration With Other Equipment

The conveyor must match the speed, height, and orientation of fillers, checkweighers, sealers, metal detectors, and palletizers. Flat belts ensure stable weighing and sealing, while incline conveyors move finished bags to higher palletizing points. Proper integration prevents backups and keeps the line synchronized.

Quick Selection Examples

Use these guidelines as a practical shortcut when determining which conveyor type best fits your application:

Flat Belt Conveyor: Best overall choice for moving filled bags, cartons, or containers between packaging stations. Ideal when product orientation must remain stable, for example, feeding checkweighers, metal detectors, or sealers. Excellent for most downstream bag-handling needs.

Cleated Belt Conveyor: The right choice when the conveyor must travel up a steep incline and product slippage is a concern. Cleats maintain spacing, prevent rollback, and ensure metered flow into elevated hoppers or palletizing systems.

Troughed Belt Conveyor: Recommended for powders, granules, and loose bulk materials that need to stay centered on the belt. Perfect for upstream processing, transferring raw materials, or feeding bagging equipment with minimal spillage.

Modular Plastic Belt Conveyor: Best for operations with strict sanitation requirements. Ideal for food, dairy, and specialty chemical facilities where washdown, corrosion resistance, or belt longevity is critical.

Roller Bed Conveyor: The most efficient option for heavier bags or long horizontal distances. Rollers reduce friction, lower power usage, and support larger or bulkier loads commonly found in warehouse, distribution, or palletizing zones.

These examples give operators and engineers a direct, high-value starting point to match a conveyor type with real-world application needs.

The Role of Conveyor Belts in Automated Dry Bulk Packaging Lines

Conveyor belts keep automated dry bulk packaging lines running smoothly by moving materials and filled bags consistently from one station to the next. They eliminate gaps, prevent surges, and ensure each machine receives product at the right pace.

Accurate Weighing and Filling: Conveyors deliver a steady, controlled feed into fillers, which is essential for weight accuracy. This consistency helps small bag fillers and bulk bag fillers maintain precise dosing and reduces rework or rejected bags.

Reduced Manual Handling: By automatically transferring bags between stations, conveyors minimize lifting, carrying, and repositioning. This lowers labor requirements, reduces fatigue, and allows operators to focus on quality and line monitoring.

Faster Throughput: Continuous movement increases bags-per-minute output. With smoother transfers and fewer stoppages, fillers, sealers, and palletizers operate closer to full capacity, improving overall line efficiency.

Improved Plant Safety: Conveyors reduce operator exposure to heavy bags, repetitive motions, and congested work zones. Better bag control and built-in safety features also help prevent slips, strains, and equipment-related injuries.

Enabling Seamless Integration Across Packaging Equipment: Modern dry bulk packaging lines require conveyors that align with the speed, spacing, and orientation needs of multiple machines. Proper conveyor selection ensures smooth transitions between:

Bulk bag (FIBC) fillers

Checkweighers, metal detectors, and sealing units

Palletizing systems, manual, semi-auto, or robotic

Conveyors ensure the product arrives at each machine in the correct position, at the right rate, and at the proper elevation. This level of integration allows the entire packaging line to operate as a synchronized system, improving reliability, consistency, and overall output.

How H&H Design Mfg Delivers Complete Conveyor Solutions

Many dry bulk packaging lines struggle with bottlenecks between filling and secondary processes and inconsistent bag transfer that causes stoppages, issues that reduce throughput and increase labor costs. H&H solves these with engineered conveyors that deliver smooth material handling and seamless integration into complete automated lines.

Their conveyor systems are built to support reliable transfer, orientation, conditioning, and quality control from start to finish. Below is a quick-reference overview of H&H’s conveyor lineup and how each model supports complete dry bulk packaging lines:

Conveyor Series | Primary Function | Key Features | Typical Application |

|---|---|---|---|

Bag sealing transport | Adjustable height & speed, sealer integration | Smooth movement through bag sealers | |

Standard conveyor | Material transfer with centered transport | Core flat/transfer conveyor for packaging lines | |

Vertical/incline transfer | Powered incline/decline, adjustable height, bag compression | Transfers bags vertically with compression before palletizing | |

Bag conditioning | Dual-belt compression, adjustable gap | Conditions bags for stable stacking & palletizing | |

High-speed bag handling | Reinforced dual-belt design, dense material flattening | Heavy-duty high-throughput bagging lines | |

QC conveyor | Integrated digital weighing & reject system | Precision weight control and reject/divert functionality | |

Compact transfer & orientation | Tight transfer points, friction top, 90°/180° rotation | Orientation & transfer in space-constrained layouts | |

Specialized conveyors | Custom and specific transfer roles (details per request) | Tailored for unique packaging line needs |

H&H conveyors are engineered not just for transport, but to fit specific line roles, from sealing and weighing to conditioning and orientation. They are delivered as part of complete dry bulk packaging systems.

Conclusion

Choosing the right conveyor belt is essential for keeping a dry bulk packaging line running efficiently. Matching the conveyor to your material type, plant layout, throughput requirements, and integration needs ensures smooth flow, accurate weighing, and consistent downstream performance.

H&H Design Mfg delivers more than conveyors; they engineer complete, integrated bagging and packaging lines. With systems designed for reliability, accuracy, and long-term durability, H&H conveyors enhance every stage of the process, from filling and sealing to conditioning and palletizing.

Looking to upgrade or integrate conveyors into your packaging line?

Talk to an H&H engineer about your application.

FAQs

1. Which conveyor is best for moving filled bags?

A flat belt conveyor is typically the best choice for moving filled bags because it provides a stable surface, consistent tracking, and smooth transfer into sealers, checkweighers, and palletizers. For heavy bags or long runs, a roller bed conveyor may offer better efficiency.

2. How do I choose the right conveyor belt for powders or granules?

For powders, troughed belts or auger-fed systems help maintain material control and reduce dust or spillage. Granules and pellets usually run well on flat belts or troughed belts, depending on flowability and transfer distance. Material behavior is the primary determinant.

3. Can conveyor belts be integrated with automated bagging lines?

Yes. Modern conveyors are designed to integrate seamlessly with bag fillers, sealers, checkweighers, metal detectors, and palletizers. H&H systems are specifically engineered to match line speed, elevation, and orientation requirements for smooth, continuous operation.

4. Are cleated belts or incline conveyors better for elevation changes?

Both are effective, but cleated belts excel when handling powders, pellets, or bags on steeper inclines where slippage is likely. Standard incline conveyors are suitable for moderate angles or when handling stable packages like boxes or filled bags.

5. What conveyor type is best for dusty or fine materials?

Troughed belts or enclosed conveyors work best because they keep fine material centered and minimize dust escape. For extremely dusty environments, slower belt speeds or controlled feed devices may also be necessary.