Industrial conveyor systems decide whether production runs clean or stalls without warning. Throughput, worker safety, and consistency depend on how well the system handles real material behavior. Belts slip and rollers chatter when designs are not matched to abrasive, sticky, or dust-prone products. How many times has a single stoppage forced you to pause a shift or scramble maintenance?

Does your current system offer safe access, proper hopper geometry, and stable operation under load? This guide will walk through proven USA manufacturers and when a specialized partner matters more than a standard model.

Quick Insights:

Different conveyor makers solve different problems. Some excel at delicate packaged goods, others at vertical movement or automation, while only a few can engineer around difficult powders, abrasive loads, or space-restricted plants.

Customization is not a luxury, it is a requirement when material behavior becomes unpredictable. This is where companies like H&H Design & Manufacturing stand out, because they build around flow physics, site geometry, and failure modes instead of catalog specs.

Packaging-focused manufacturers shine when product stability matters more than brute strength. Span Tech or UNI-PAK handle bottles, trays, pouches, and washdown environments better than heavy industrial vendors.

Vertical and layout-constrained operations need specialized equipment. Ryson’s spiral systems replace long incline runs and preserve spacing, which warehouse and multi-level packaging lines cannot achieve with standard conveyors.

Automation and distribution demand ecosystem-level providers. UMD and Bastian Solutions integrate conveyors with robotics, software, and multi-facility deployments, far beyond what small fabrication shops can deliver.

Top 10 Industrial Conveyor Manufacturers Based in the USA

Choosing the right conveyor partner is about performance under real conditions, not glossy branding. This list looks at material handling fit, uptime, service culture, and how well a system holds up once it hits the floor. Some manufacturers shine in bulk solids, others in packaging or vertical movement. The aim is simple: help you match your needs to the company that can actually deliver.

1. H&H Design & Manufacturing: Custom Industrial Conveyor Systems for Complex Materials

You choose H&H Design & Manufacturing when standard conveyors fail under real material conditions. Their engineers design around abrasive powders, hygroscopic bulk, unstable loads, and plant layouts that never match catalog dimensions. Every build starts with your material behavior and floor geometry, not a generic model. If you are tired of repeated belt wear, dusting, or surge feeding, this is the team you call.

What you get with H&H

Full lifecycle control: Design, fabrication, commissioning, and service handled in-house for consistent output and clear accountability.

Custom engineering for flow behavior: Belt surface, scraper systems, structure, and pitch tuned to abrasive, sticky, or caking materials.

Rapid adaptation to line changes: New SKUs or process shifts handled directly by engineers instead of support tickets.

Tech Packaging legacy upgrades: Maintains and improves existing Tech Pack systems with deep knowledge of tolerances and mechanics.

Built for plant realities: Layouts tailored to tight retrofits, elevation changes, unstable packaging, and constrained workspaces.

Below is a table of commonly used systems. You should match your material and process needs, not just your budget.

Series | Type / Core Feature | Practical Uses |

Flat Top Modular Belt standard duty | Food packaging, bottling, carton transport, assembly | |

Curved Flat Top 90° or 180° | Pharma lines, packaging reroutes, footprint constraints | |

Flush Grid / Perforated | Cooling, drying, draining, seafood and bakery processing | |

Friction Top Surface | Incline and decline movement, beverage elevation, pouch transport | |

Roller Top / Low Back Pressure | Accumulation, sorting, merging, diverting in logistics | |

Raised Rib / Grip Top | Inclined slips, tray handling, frozen goods, high-friction scenarios | |

Heavy Duty Modular | Automotive parts, metal stamping, recycling, pallet transfer | |

Tight Transfer Small Pitch | Small part transfer, snacks, confectionery, pharma packaging |

Limitations worth considering

Custom engineering requires clear input: You need to provide accurate material data, duty cycle expectations, and space constraints; vague specifications slow the process.

Not a “fast catalog shipper”: If you want a quick, prebuilt conveyor without consulting engineering, H&H will not be the best fit.

Project scope matters: Their strength is solving difficult problems; very small projects with no mechanical challenge may be better served by off-the-shelf suppliers.

With H&H Design & Manufacturing, you get a partner who understands that your next downtime event is not a service ticket. It is lost production hours, forklift waiting time, and a floor crew scrambling to clean or refeed product. This is why clients in the US, Canada, Mexico, South America, and the Middle East keep them on their vendor list.

Ready to stabilize tubular or cylindrical bags without constant operator adjustment? The Series 152 conveyor keeps every unit centered, protected, and moving cleanly through your line. Tell us your bag type and space constraints and we’ll tailor the system to your process!

2. Span Tech Conveyors: Modular Conveyor Systems for Complex Packaging Lines

You turn to Span Tech when packaging lines demand smooth handling of small or delicate items. Their modular conveyor links create curved paths and controlled transitions without sudden drops or transfer failures. If your line needs tight turns or accumulation without crushing product, this system fits.

Where Span Tech delivers measurable value

Consumer goods and packaging lines: Handles bottles, pouches, trays, wrapped snacks, cosmetic containers, and small SKU formats with consistent spacing.

Stable transfers and accumulation: Modular links reduce vibration and pressure build-up, which protects lightweight or fragile products.

Curved and directional changes: 90 or 180 degree paths keep your layout compact without needing multiple independent conveyor segments.

Limitations to consider

Not suited for abrasive bulk, metal scrap, raw aggregates, or heavy industrial solids.

Not ideal for washdown environments that require heavy stainless construction or impact resistance.

3. UMD Automated Systems: Industrial Conveyor and Automation Integrations

You choose UMD when conveyors need to interact with machines, not just move products. Their designs integrate with OEM robotics, vision systems, or automated cells without losing flow stability. If your operations rely on coordinated workstations or synchronized production steps, UMD fits well.

Strong use cases

Assembly lines: Conveyor motion is matched to part presentation, screwdriving stations, or inspection points.

Manufacturing cells: Controlled indexing for welding, machining, printing, or labeling.

Automotive support: Engineered layouts for component delivery, small fixtures, harness routing, or subassembly movement.

Important consideration

Their systems often require longer planning cycles and defined process steps. If you only need standalone conveyor movement without automation, UMD is unnecessary complexity.

4. Integrated Solutions Outsourced Manufacturing: Custom Fabricated Conveyors for Low-Volume Needs

You work with Integrated Solutions when you have a small project that requires quick hands-on fabrication. They specialize in custom-built conveyors for smaller teams that cannot wait for corporate-scale vendors or long quoting cycles. If you need a single workstation conveyor or a one-off layout, this group is practical.

What makes them suitable

Fabrication flexibility: They adjust frame width, guarding, supports, and drive placement to match your floor space and product size.

Fast prototyping: Ideal when you need physical trials, testing stations, or short-run equipment for validation or pilot lines.

Limitations

Their small team size limits scalability.

When you require large installs, complex integration, or multi-facility rollouts, you will outgrow their capacity.

5. Heinrich Brothers: Warehouse Conveyor Design and Material Flow

You choose Heinrich Brothers when your facility deals with pallets, cartons, or packaged SKUs that need to move smoothly through storage or outbound lanes. Their systems focus on warehouse layouts rather than dust-heavy process lines or bulk extraction. If you want clean transitions from inbound receiving to packing, this is where they fit.

Where Heinrich Brothers performs well

Pallet movement and carton handling: Roller, gravity, and motorized setups that keep pallets moving without excessive push force or forklift dependency.

Packaging flow: Lines designed to manage boxes, totes, or trays through packing, labeling, or sortation without gridlock.

Small to medium industrial setups: Ideal when you are upgrading a warehouse or distribution mezzanine without redesigning the entire building.

What to consider

Not suited for abrasive solids, metal scrap, or heavy raw materials.

Their designs are distribution-first, not bulk processing systems.

Need reliable incline and decline movement between your bagging line and palletizer? Series 153 delivers controlled vertical transfer, uniform bag compression, and stable flow.

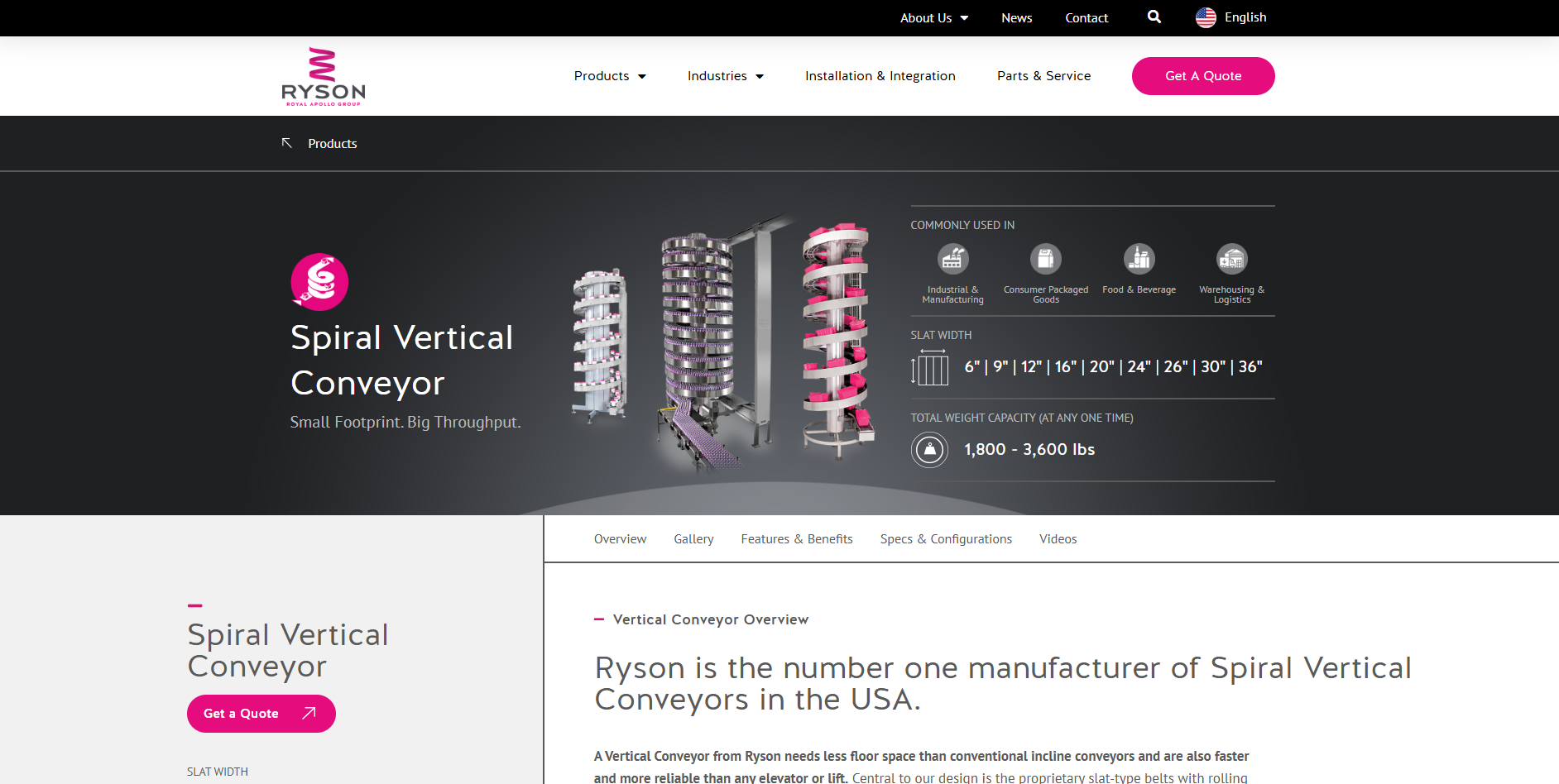

6. Ryson International: Vertical Conveyors and Spiral Conveyors

You go to Ryson when floor space is limited and you need vertical movement without building multiple independent conveyors. Their spiral designs handle elevation changes gently, keeping product spacing and flow intact. If you operate packaging lines with transitions across multiple levels, their equipment makes those shifts predictable.

Practical strengths

Space-constrained plants: Spiral movement replaces large incline or decline sections that occupy floor space.

Multi-level packaging: Smooth transitions from carton forming to filling to palletizing with controlled speed.

Gentle handling: Spiral lift reduces abrupt acceleration and deceleration, which protects fragile loads.

Not designed for

Mining-style throughput, abrasive ores, or high-impact bulk material transport.

Applications where metal wear or impact loading is constant.

7. UNI-PAK Corp.: Food and Beverage Conveyor Specialists

You choose UNI-PAK when hygiene and washdown matter more than brute strength. Their systems serve bottle lines, lightweight packaged goods, and food-grade environments where surfaces must clean easily and resist contamination. If your line needs stainless steel frames and smooth contact areas, UNI-PAK is a direct fit.

Core advantages

Washdown environments: Stainless builds that hold up to frequent sanitation cycles, moisture, and chemical cleaning.

Bottle and beverage lines: Conveyors tuned for high-volume movement of cans, bottles, and delicate packaging formats with stable spacing.

Lightweight packaged products: Snack cartons, trays, cases, and other small products kept moving without crushing or slip events.

Limitations

Not suitable for heavy industrial operations, bulk scrap, or abrasive raw materials.

They are built for cleanliness and light-to-medium duty, not extreme durability workloads.

8. Industrial Magnetics, Inc.: Magnetic Conveyor Solutions for Separation and Safety

You go to Industrial Magnetics when metal contamination is a risk that could damage downstream equipment or compromise product quality. Their conveyors use magnetic holding and extraction to capture ferrous material that traditional belts let pass. If you operate in environments where metal fragments appear unpredictably, this is a direct solution.

Where Industrial Magnetics fits best

Recycling line: Ferrous separation prevents grinders and shredders from taking unnecessary impact.

Fabrication facilities: Captures swarf, chips, and sharp scrap before they accumulate in tooling or coolant tanks.

Scrap management: Helps remove metal from bulk flow so materials can be reused or sorted without contaminating clean product.

Limits to note

They are not a full conveyor replacement. Their systems complement your main conveyor and protect it, not act as a universal transport platform.

9. Vistamation: Conveyor Procurement and Material Handling Catalog Supplier

You choose Vistamation when you already know the type of hardware you need and want it sourced quickly. Their catalog approach gives you access to multiple conveyor brands, accessories, and handling equipment through one procurement channel. If you are equipping a small warehouse or replacing individual segments, this saves you time.

Where Vistamation provides value

Component sourcing: Belts, rollers, motors, guides, packaging conveyors, and accessories available without custom design requests.

Distribution networks: Access to multiple manufacturers without juggling vendor contracts or minimums.

Mixed vendor equipment: Helpful when your facility uses products from several OEMs and you want consistent supply.

Keep in mind

They do not perform deep engineering or custom system design. If you need layouts, controls, or materials handling analysis, you will need another provider.

10. Bastian Solutions: Large-Scale Integrated Industrial Conveyor and Automation

You work with Bastian when your plant needs conveyor infrastructure tied to robotics, software, and automated storage. Their systems support enterprise-scale distribution centers, high-velocity e-commerce operations, and multi-facility rollouts. If you require conveyors that interact with sensors, pick systems, or AMRs, Bastian is a proven option.

Where Bastian stands out

Enterprise automation: Conveyor networks integrated with WMS or WCS for synchronized movement and load balancing.

Warehouse robotics: Equipment that works with robotic picking arms, AGVs, or shuttle systems without constant reprogramming.

Distribution centers: High-throughput designs for order consolidation, unit handling, and sortation at scale.

Limitations

Their scope makes the most sense for large projects. If you need a single workstation conveyor or modest fabrication, their overhead and planning cycles may be excessive.

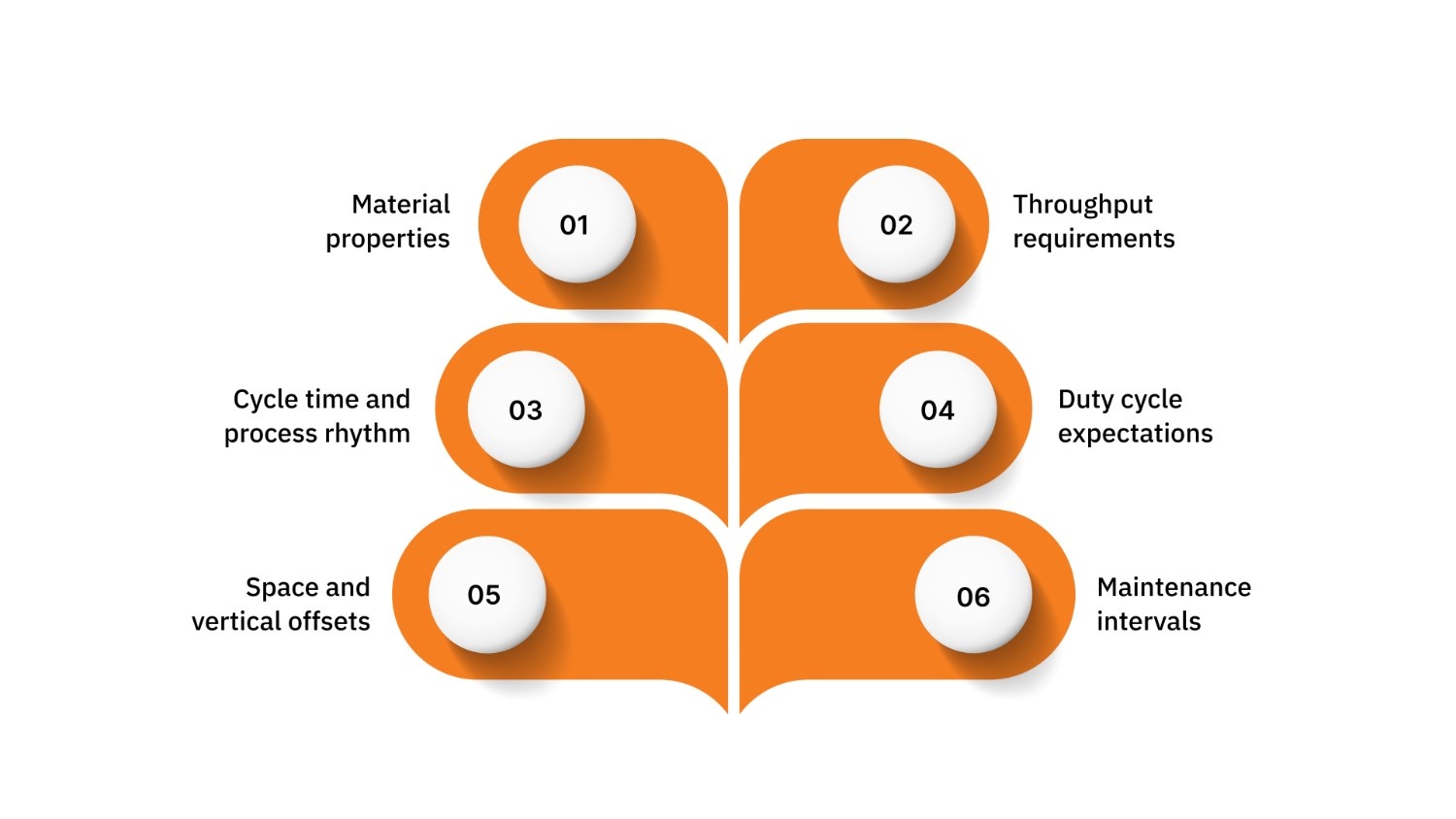

You now know who can build the conveyor you need, but manufacturers can only design as well as the information you give them. Before you ask for quotes, make sure you’re supplying more than belt length and price targets.

Practical Tips for Requesting Quotes for an Industrial Conveyor

Conveyor projects go wrong when vendors receive incomplete or unclear inputs. You may think you only need belt width, speed, and length, but those details alone do not reflect how material behaves during actual production. When you send vague specs, you force the manufacturer to guess, and the result is a system that fails once it hits your floor. A precise quote begins with real operational data.

Below is the information you should have ready before you ask any manufacturer for pricing:

Material properties: Provide particle size, abrasiveness, moisture content, and flow behavior. For powders or granules, note caking, static buildup, or dusting tendencies.

Throughput requirements: Give hourly tonnage or units per hour. If volume changes over the day, include typical and peak flow, not a single average.

Cycle time and process rhythm: If your line stops during filling, inspection, or batching, note it. Intermittent flow affects motor sizing, scraper design, and buffer capacity.

Duty cycle expectations: Specify how many hours per shift and how many shifts per week. Continuous operations need stronger drive components and belt materials than part-time applications.

Space and vertical offsets: Share floor layout drawings, elevation changes, and clearance restrictions. Tight corners, mezzanines, or low ceilings dictate curve radius, pitch, and support geometry.

Maintenance intervals: Tell the manufacturer how often you can service belts, rollers, or bearings. If downtime windows are short, you need easier access and modular replacements.

Need a conveyor that turns a stack of filled bags into a stable, pallet-ready load? The Series 154 dual-belt compression conveyor squeezes and conditions each bag for consistent stacking.

Conclusion

Selecting an industrial conveyor is not a branding decision. It is a material science decision backed by engineering reliability and the ability to support a system when the line is running at full load. The companies listed above each fit specific conditions, but the right fit always starts with how your material moves, how your facility is laid out, and how often you can afford to stop the process. Which point in your line causes the most downtime?

If you only compare belt width or price, you will end up buying replacements faster than you expect. Think about the operators who will work beside the conveyor, the maintenance crew who will clean and tension it, and the real cost of losing a shift to powder buildup or misalignment. Are you buying components or long-term performance?

H&H Design & Manufacturing is ideal when materials misbehave, when geometry is tight, or when reliability matters more than catalog price. If you want a conveyor designed around your material and not a brochure, contact us to discuss your line requirements.

FAQs

Q: What conveyor belt surface should I choose for products that slip or rotate during incline transport?

A: You should choose a friction or grip-top surface. It maintains traction on angles and prevents cartons, trays, or lightweight packages from drifting backward. This keeps spacing stable and reduces operator intervention.

Q: How does conveyor speed affect small product stability during accumulation zones?

A: Higher speeds increase vibration and micro-impacts that move items out of alignment. Lower controlled speeds keep spacing consistent, protect delicate packaging, and reduce merge jams. Always match speed to the smallest product footprint.

Q: When should you use stainless frames even if the product is not food-grade?

A: Stainless frames resist moisture, washdowns, and chemical exposure, which avoids corrosion and structural fatigue. They also provide smoother surfaces that reduce debris buildup in humid or abrasive work areas. This extends equipment life and cleaning intervals.

Q: What type of conveyor is best for parts that shed chips or metallic debris during processing?

A: A system with magnetic extraction or scrap capture prevents fragments from reaching motors or rollers. It protects tooling and reduces the risk of operator injury caused by loose metal. Contaminants are removed before they travel further down the line.

Q: Why do some conveyors require controlled indexing rather than continuous movement?

A: Processes like welding, inspection, or precise filling need a defined stop point so equipment can operate accurately. Continuous motion introduces tolerance drift, leading to misalignment and wasted material. Indexing keeps timing predictable for each workstation.

Q: When is it better to buy multiple smaller conveyors instead of one long system?

A: Smaller modular sections make maintenance faster because a single failure does not shut down the full line. They allow you to isolate issues, replace drive components, and tune specific segments. This reduces downtime and keeps production running.