When fine powders are handled carelessly in manufacturing, what seems like a routine task can quickly spiral into a serious health or safety hazard. According to a recent global estimate, occupational exposure to dust and fine particulate matter contributes to as many as 450,000 work‑related deaths per year, underscoring how dangerous uncontrolled powder handling can be.

When dust escapes into the air unnoticed, during transfer or conveying, it can cause respiratory illness, combustible‑dust explosions, product contamination, or regulatory compliance failures. Without the right equipment and controls, every shift carries risk.

That’s why investing in dedicated, industrial‑grade powder‑handling equipment engineered for safe transfer, containment, and dust control is a necessity.

In this blog, we’ll walk you through the essential equipment and practices needed for safe fine‑powder handling, helping you protect your workers, maintain product quality, and avoid costly downtime.

Key Takeaways

Industry Challenges: Safe powder handling varies by industry, with challenges like dust contamination, fire hazards, and worker exposure. Food, pharma, and chemicals need specialized equipment to manage these risks.

Safety Equipment & Measures: Dust collection systems, enclosed conveyors, and explosion protection are crucial to manage airborne dust, preventing contamination, and maintaining safe operations.

US Regulatory Compliance: Compliance with OSHA, NFPA, and FDA/FSMA regulations is vital to avoid fines and ensure safety, making reliable equipment and documentation critical for audits.

Advanced Technologies: IoT dust collectors, high-containment systems, and automated handling solutions improve safety by providing real-time monitoring, reducing dust exposure, and enhancing process control.

H&H Equipment Solutions: H&H Design & Manufacturing’s equipment, like the Series 52 Small Bag Filler and Series 110DS Bulk Bag Filler, supports safe, accurate, and efficient powder handling.

Benefits of Safe Handling of Fine Powders: Why It Matters

Fine powders behave unpredictably, like they float, cling, compact, or ignite depending on the environment. For industries like food, chemicals, and pharmaceuticals, where quality, safety, and uptime define success, safe powder handling is important for operational reliability and compliance.

Reduced downtime and higher throughput: controlled material flow prevents blockages, misfeeds, and cleanup stoppages, keeping lines running.

Better product integrity: contamination control, correct dosing, and hygienic transfer improve consistency, purity, and shelf life.

Lower workforce risk: effective dust containment limits inhalation hazards, skin exposure, and combustible dust ignition.

Improved compliance outcomes: proper handling helps satisfy OSHA, NFPA, EPA, FDA, and GMP requirements, shortening inspections and audits.

Less waste and tighter cost control: accurate dosing and dust capture reduce product loss, rework, and disposal costs.

These benefits apply across manufacturing, but the path to achieving them varies significantly. A flour mill faces different hazards than a pharmaceutical cleanroom, and a fertilizer plant operates under constraints unlike a dairy facility.

Industry-Specific Challenges in Safe Fine Powder Handling

Powder risks aren’t the same across sectors. Each industry faces unique operational pressures, contamination risks, and regulatory demands, which is why equipment selection becomes application-driven rather than generic.

Food Processing

Food powders like flour, starch, and spices create dust clouds that threaten hygiene and explosion risk. Plants need enclosed fillers, dust-tight conveyors, and easy-clean designs to meet FDA/FSMA expectations and prevent cross-contamination between recipes.

Pharmaceutical Manufacturing

Ultra-fine APIs require strict containment to protect operators and avoid batch contamination. Accurate weigh fillers, sealed discharge systems, and validated cleaning procedures are essential to meet cGMP and OSHA exposure limits.

Chemical & Specialty Materials

Powders ranging from pigments to catalysts may be toxic, corrosive, or combustible. Explosion-rated conveyors, anti-static equipment, and engineered ventilation become critical to avoid ignition, corrosion damage, and airborne exposure incidents.

Agriculture & Fertilizer Plants

Moisture-sensitive powders can cause cake, bridge, or degrade product quality. Reliable flow-conditioning equipment, controlled discharge systems, and rugged bulk handling machines are required to manage large batches without clogging or downtime.

Mining & Mineral Processing

Abrasive powders like cement dust or mineral fines cause excessive wear on machinery and present serious inhalation hazards. Plants benefit from heavy-duty enclosed conveyors, filters, and durable liners to minimize airborne exposure and extend equipment life.

Dairy & Nutraceuticals

Ingredients such as whey, milk powder, or supplements are highly aeratable and hygiene-sensitive. Gentle transfer systems, enclosed bag filling, and precise weighing controls help avoid dusting, contamination, and wastage.

Recognizing the unique risks in your sector is the first step. The next is building a defense system around those risks, one that combines equipment, engineering, and operational discipline.

Essential Safety Equipment & Measures for Fine Powder Handling

Handling powders safely requires more than good intentions — it demands a layered approach combining the right equipment, engineering controls, and disciplined procedures. Below are the core safety measures plants should implement when working with fine powders.

Dust Collection & Filtration Systems

Install industrial‑grade dust collectors (baghouses, cartridge filters, cyclones) to capture airborne powder at transfer points, hoppers, and discharge zones. This minimizes respiratory hazards, dust build-up, and contamination risks.

Ensure the dust collection system includes explosion protection features, like vents, isolation valves, or suppression mechanisms, when handling combustible powders like flour, sugar, or certain chemicals.

Enclosed Conveying, Transfer & Containment Systems

Use sealed conveyors, transfer chutes, or pneumatic transfer systems to prevent dust escape during powder movement. Open or poorly sealed conveyors increase dust dispersion and risk.

Incorporate static‑control measures: grounding or bonding of metal parts, using conductive materials where needed. This helps prevent static discharge, which is a common ignition source in dust‑handling operations.

Explosion & Ignition‑Risk Control Systems

For combustible dust environments, install explosion vents, suppression systems or isolators, spark arrestors, and flame‑safe valves to mitigate explosion or fire risks if a dust cloud ignites.

Maintain proper housekeeping: regular cleaning of horizontal surfaces, ducts, and equipment to avoid dust layering.

Ventilation and Local Exhaust / Source Capture

Use local exhaust ventilation (LEV) or hood‑based suction at dust‑emitting points (fill ports, bag dump stations, mixers) to immediately capture airborne particles rather than allowing dust to disperse inside the plant.

Combine general room ventilation with filtration and dust‑collection to keep ambient dust concentrations below occupational exposure limits and reduce inhalation hazards.

Accurate Weighing, Feeding & Sealed Point‑of‑Transfer Equipment

Use enclosed or sealed feeders, weighers, fillers, or bag‑fill systems, especially for powders that are fine, dust‑prone, or sensitive, to minimize dust escape and ensure accurate dosing.

Avoid open transfer between containers (e.g., manual scooping or open pouring), which vastly increases dust liberation and exposure risk. Sealed, automated systems are far safer for powders.

Maintenance, Inspection & Housekeeping Protocols

Establish routine cleaning schedules and inspection protocols for dust collection systems, filters, ducts, and transfer lines. A small dust layer on surfaces or hidden areas can become an ignition hazard.

Implement a hazard‑awareness program including employee training on dust risks, proper handling procedures, and emergency response. Well-trained staff complement engineered controls effectively.

Use of PPE & Administrative Controls (Where Needed)

Where engineering controls can’t eliminate exposure fully, supply suitable PPE, respirators, gloves, and eye protection as a last line of defense.

Maintain up‑to‑date documentation: safety data sheets (SDS), standard operating procedures (SOPs), maintenance logs, and a history of dust‑control checks for compliance and audits.

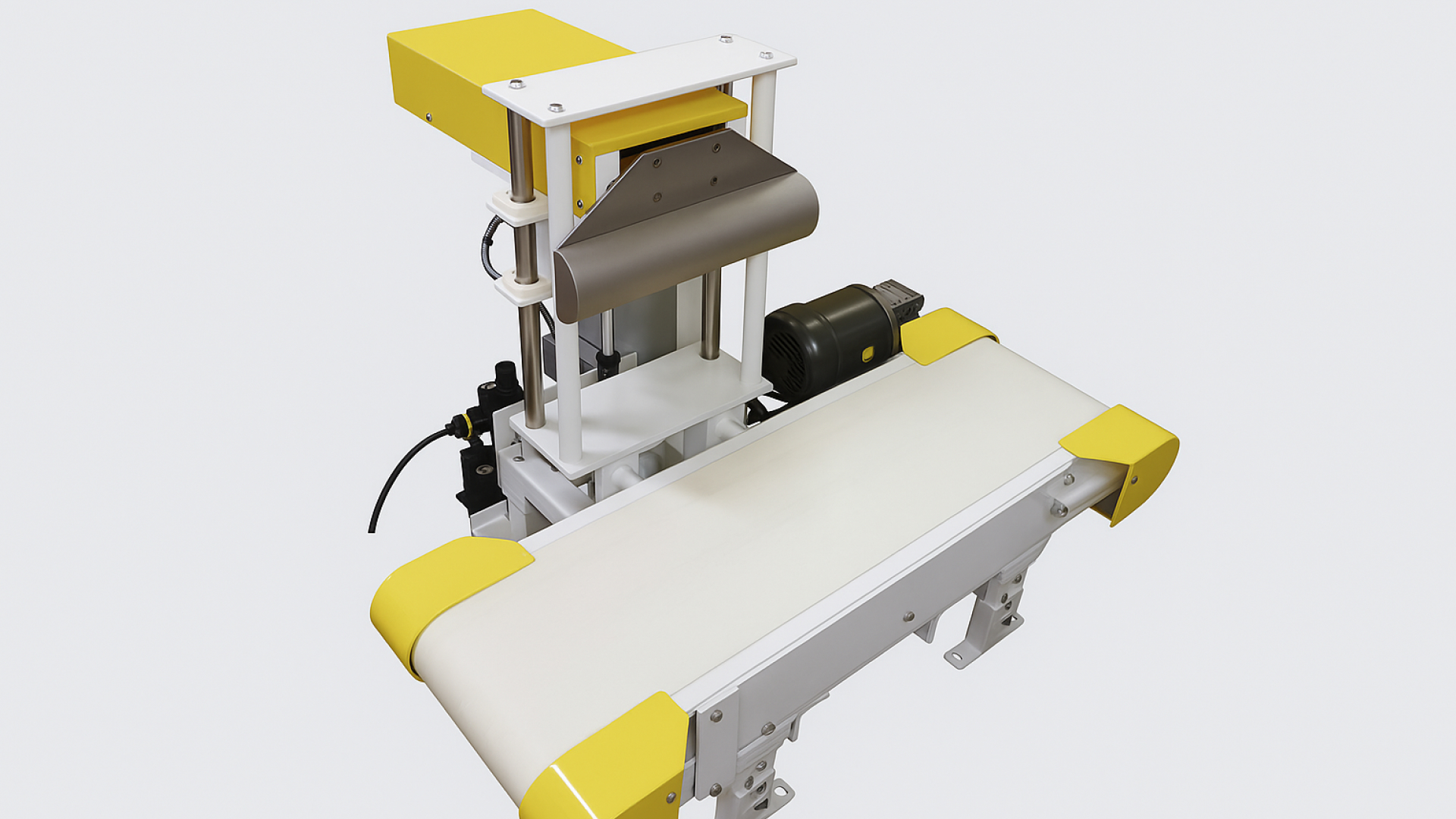

H&H Design & Manufacturing specializes in designing and producing high-performance powder handling equipment, such as Series 200X, for powder granules and flakes for industries like food, chemical, and plastic, where safety and precision are paramount.

US Regulatory Standards Governing Safe Fine Powder Handling

Safe powder handling isn’t just good practice in the US; it is governed by strict regulatory frameworks across safety, hygiene, contamination control, and explosion prevention. Failing to comply can lead to OSHA citations, NFPA violations, batch recalls, or shutdowns during audits.

OSHA Respiratory & Exposure Standards: Under OSHA 29 CFR 1910, employers must protect workers from airborne dust exposure, including nuisance dust and hazardous particulates.

NFPA Combustible Dust & Explosion Safety: NFPA 652 and NFPA 61 regulate combustible dust management across industries such as food, agriculture, and chemicals. They cover ignition control, explosion-vented dust collection, and more.

FDA / FSMA Requirements for Food & Dairy Powder: For food powders like flour, whey, spices, or ingredients, FSMA requires contamination control, allergen segregation, and hygiene-focused equipment.

cGMP / FDA Requirements for Pharmaceutical Powders: Pharmaceutical plants must follow cGMP guidelines for cleanability, containment, and traceability when dosing powders.

EPA Air Quality & Emission Limits: When powders release dust into the atmosphere, EPA rules apply under the Clean Air Act. Industrial facilities are expected to manage fugitive emissions and maintain proper capture/filtration

NTEP / Weighing System Compliance: When fillers include weighing functions, accuracy must align with National Type Evaluation Program (NTEP) or OIML compliance. H&H’s equipment incorporates digital weighing, filling, and calibration support. These certifications matter for food, chemical, and agricultural packaging.

Compliance establishes the minimum standard. Forward-looking facilities are now adopting next-generation systems that exceed baseline requirements while improving operational visibility and control.

Advanced Technologies for Safe Fine Powder Handling

As industries move towards greater efficiency, safety, and compliance, new technologies are revolutionizing powder handling systems.

IoT-Enabled Dust Collection Systems: Modern dust collectors now feature IoT sensors for real-time monitoring of airflow, pressure, and emissions. These smart systems allow for predictive maintenance and reduce downtime.

High-Containment Transfer Solutions: Valves, isolators, and split butterfly valves maintain strict control during material transfer, ensuring minimal operator exposure. These technologies are apt for the pharmaceutical and chemical industries.

Integrated Automation & Process Control: Automation connects all components, from conveyors to dust collectors, streamlining operations and providing seamless, safe powder handling.

Technology enables safer operations, but effectiveness depends on how well equipment is designed for real-world conditions. This is where purpose-built solutions make the difference between theoretical safety and actual risk reduction.

Why Safe Handling Matters, And How H&H Fixes It

When fine powders aren’t handled properly, plants face serious risks: dust exposure and contamination. These issues threaten worker safety, product integrity, and operational reliability, all critical for plants in food, chemicals, agriculture, or bulk‑powder industries.

H&H Design & Manufacturing builds equipment with precisely those risks in mind. Their machines combine dust containment, accurate dosing, enclosed handling, and rugged industrial‑grade construction.

Series 52 Small Bag Filler: suited to open‑mouth bag filling of food‑grade powders. It offers tool‑less auger removal for quick cleaning or changeovers, minimizing cross‑contamination and streamlining maintenance.

Series 54 Small Bag Filler: Engineered for fine powders (cement, fly‑ash, pigments, and similar materials), the Series 54 uses a primary + secondary auger system to combine speed and fine‑feed accuracy

Series 110DS Bulk Bag Filler and Series 330E Bulk Packaging System: for large volumes and super‑sack packaging. Their heavy‑duty scales, inflatable dust‑tight fill heads, and adjustable frames provide safe, contained filling of bulk bags, even with dusty or challenging powders.

With these advanced, purpose-built systems, H&H addresses the specific challenges of powder handling, ensuring your operations run smoothly and safely.

Conclusion

Safe handling of fine powders is a critical factor in maintaining worker health, operational efficiency, and product quality. From dust collection and explosion prevention to precise dosing and regulatory compliance, adopting the right equipment and practices ensures your facility runs smoothly and stays compliant.

As highlighted in this blog, industrial-grade systems designed for containment, accurate handling, and safety are essential to mitigate risks and improve performance.

H&H Design & Manufacturing understands the complexities of safe powder handling, where we deliver equipment built to minimize risks and optimize powder processing.

Contact us for expert packaging solutions for your production needs.

FAQs

What PPE is needed for powder handling?

For powder handling, workers should wear respirators, gloves, eye protection, and protective clothing to avoid inhaling dust and minimizing skin contact with hazardous materials. In high-risk environments, hearing protection may also be required for noise control.

What equipment is used for powder mixing?

Common equipment for powder mixing includes blenders, mixer drums, and vibratory shakers. For uniform blending, rotary blenders, high-shear mixers, and paddle mixers are often used depending on the material's characteristics.

What is powder processing equipment?

Powder processing equipment includes machines that handle milling, mixing, granulating, and sieving powders. Examples include hammer mills, ball mills, mixers, and sifters used to process raw materials into fine powders suitable for manufacturing.

How to increase powder flowability?

Improving powder flowability can be achieved by adding flow aids such as anti-caking agents, adjusting moisture content, and using vibrators or fluidized beds to reduce compaction and encourage smoother movement through equipment.

What are the 4 P's of GMP?

The 4 P's of Good Manufacturing Practice (GMP) are: People, Premises, Processes, and Products. These elements ensure that pharmaceutical and food products are consistently produced and controlled according to quality standards.