When bulk materials like powders, granules, or sludges pile up in silos and chutes, relying on the wrong conveyor design can bring your production line to a halt. Unplanned downtime is a serious drain; manufacturing plants can lose thousands of dollars per hour when conveyors fail.

In such scenarios, a well‑designed Ribbon Screw Conveyor can make all the difference. With the right type of ribbon‑flight configuration, you can transport sticky, viscous, or dusty materials smoothly, avoid any blockages, wear, or premature shutdowns.

In this article, we’ll explore the different types of ribbon screw conveyor flights and show you which design fits your material and process needs, helping you keep your line running reliably and efficiently.

Key Takeaways

Types of Ribbon Screw Conveyors: The main types are Integral‑Leg, Post‑Type, and Double‑Flight, well-suited for varying material behaviors like stickiness, cohesiveness, and flow consistency.

Pros and Cons: The Integral‑Leg Ribbon Screw is cost-effective but not suited for sticky materials. Post‑Type Ribbon Screw is ideal for sticky materials, but comes with fabrication costs. Double‑Flight Ribbon Screw excels in mixing but sacrifices throughput and requires maintenance.

Industry Applications: Ribbon screw conveyors are key in industries like food processing, chemicals, agriculture, pharmaceuticals, mining, and wastewater treatment, particularly for sticky or cohesive materials.

Customization for Specific Needs: Custom ribbon screw conveyors can be designed to handle materials with unique properties, improving flow and minimizing downtime.

H&H Design & Manufacturing Expertise: H&H designs and manufactures custom conveyor systems, including flex screw conveyors and others, to meet specific material handling and process requirements.

What is a Screw Conveyor?

A screw conveyor is a mechanical device used to move bulk materials like powders, granules, pellets, etc, from one place to another using a rotating helical screw (also called flighting or auger) inside a tube or trough. This method works for a wide range of materials in horizontal, slightly inclined, or vertical setups. Screw conveyors are widely used across the food, agriculture, and chemical industries.

What is a Ribbon Screw Conveyor?

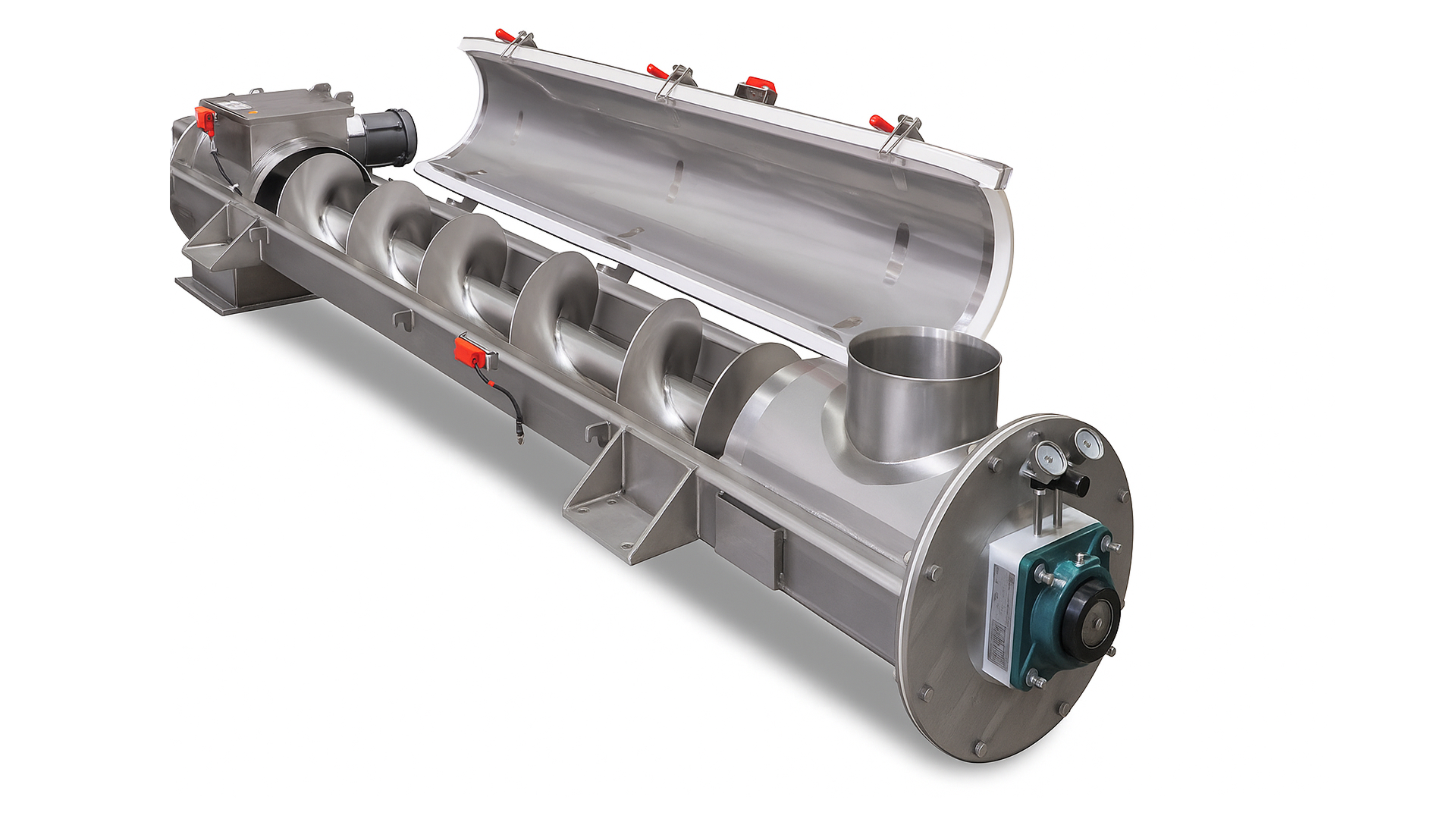

A ribbon‑screw conveyor is a variation of the standard screw conveyor in which the “flighting” isn’t a tight helical blade wrapping closely around the shaft. Instead, the flight is shaped as a relatively flat or wide “ribbon,” leaving space between the shaft and the ribbon’s inner edge.

This open profile reduces the contact area where material tends to cling or build up, making it much better suited for sticky, viscous, cohesive, or hygroscopic bulk solids

Types of Ribbon Screw Conveyor System

Bulk material handling rarely follows a “one-size-fits-all” approach. Material behavior, such as stickiness, abrasiveness, and the tendency to build up, varies based on factors like powder/wet content, moisture, and density. Choosing the wrong flight design can lead to clogging, build-up, uneven flow, and an increase in maintenance, ultimately causing downtime.

Integral‑Leg Ribbon Flight

In this design, the ribbon flight is formed with integral support (leg) that’s part of the ribbon itself, welded or fabricated around the central pipe so the ribbon and its supporting leg are continuous. This essentially treats the ribbon flight similar to a standard sectional flight, but cut/formed to leave space between the flight and the shaft.

Pros and Cons of Integral-Leg Ribbon Flight

Pros | Cons |

More cost‑effective to manufacture than post‑type ribbon screws, since fabrication uses a similar process to standard sectional/flight screws. | Internal geometry still has more surface/shaft contact compared to the post‑type. For very sticky, viscous, or highly cohesive materials, buildup may still occur. |

Simpler/widely available design, easier to source and deliver compared with other ribbon‑flight variants. | Less effective in handling extremely sticky or hygroscopic materials. |

Suitable for moderately sticky or semi‑cohesive materials. | Less flexibility for easy maintenance or ribbon replacement (since ribbon flight is welded integrally). |

Post‑Type Ribbon Flight

A post‑type ribbon screw conveyor mounts the ribbon‑flight on discrete round‑bar posts (spaced around the central shaft), rather than welding the ribbon (and its support) directly to the shaft. This creates a more open internal geometry, reducing material contact area near the shaft, which helps prevent build‑up when handling sticky, viscous, or cohesive bulk materials.

In this design, the ribbon flight sits on the posts; the posts hold the ribbon clear of the shaft, creating a gap between the shaft and the flight, further helping with the free flow of materials.

Pros and Cons of Post‑Type Ribbon Flight

Pros | Cons |

Reduced contact area near the shaft lowers the risk of material build‑up, sticking, or caking. | More complex fabrication compared to the standard screw due to additional posts + welding. |

Easier maintenance and ribbon replacement, since ribbon is mounted on posts rather than fully welded as part of the shaft, making it easy for service or repair. | Slightly more complex internal geometry, if not properly designed or maintained, may require more precise alignment, especially for abrasive or heavy materials. |

Better suited for highly sticky or cohesive materials, offers better flow and reliability | Possibly higher initial cost vs simpler screw conveyors. |

Double‑Flight Ribbon Screw

A double‑flight ribbon screw conveyor uses two ribbon flights on the same shaft: an outer ribbon and an inner ribbon (smaller diameter). The two flights are typically “opposite‑handed,” so as the screw rotates, one flight moves material forward while the other creates a counter‑flow. This helps in both conveying and gently mixing/blending of bulk materials.

Pros and Cons of Double‑Flight Ribbon Screw

Pros | Cons |

Handles sticky, viscous, or cohesive materials more reliably, lowering the risk of build‑up or clogging. | More complex fabrication than single‑flight or standard screws — two flights need precise alignment, increasing cost and lead time. |

Offers gentle mixing/blending while conveying, improving homogeneity for powders/granules. | Reduced volumetric capacity compared to standard single‑flight screws, and mixing action reduces throughput per revolution. |

Provides more uniform discharge, helps avoid surges or segregation. Beneficial for sensitive processes (e.g., blending before bagging). | Higher maintenance complexity, correct clearances, and periodic inspection are needed to avoid blending irregularities or mechanical issues. |

Each ribbon flight configuration addresses different material challenges, from moderate stickiness to extreme cohesion. These design advantages have made ribbon screw conveyors essential equipment across sectors that handle difficult bulk materials daily.

Application of Ribbon Screw Conveyor Used Across Industries

Ribbon screw conveyors are widely used across various industries for transporting and handling bulk bag equipment, especially those that are sticky, cohesive, or hygroscopic. Here is what makes them ideal for food, chemicals, agriculture, pharmaceuticals, and more.

Food Processing: Ribbon screw conveyors are used to transport and blend dry powders, grains, spices, and sticky ingredients like flour and sugar. The ribbon design helps prevent build-up during blending and packaging.

Chemical Manufacturing: These conveyors move sticky, abrasive chemicals, pigments, and additives. The open ribbon design reduces material build-up or sticky powders in continuous chemical processes.

Agriculture & Fertilizers: Ribbon screw conveyors are used for transporting fertilizers, seeds, grains, and animal feed. The ribbon flight reduces clogging from sticky or cohesive materials, and it handles delicate agricultural products well.

Mining & Construction: Used for conveying minerals, sand, cement, and abrasive materials, ribbon screw conveyors are ideal for sticky or wet materials in mining.

Pharmaceuticals: Ribbon screw conveyors transport fine powders, chemicals, and formulations in pharmaceutical processes. The design helps avoid contamination.

Dairy & Food Ingredients: Used to convey dry dairy ingredients, milk powders, and nutritional supplements, ribbon screw conveyors ensure consistent flow and prevent clogging in sticky, powdery dairy products.

Wastewater Treatment: Ribbon screw conveyors are used to move dewatered sludges or similar waste materials. The open ribbon design reduces the risk of clogs and material build-up.

Understanding where ribbon screw conveyors excel is one thing; getting the right configuration for your specific operation is another. Off-the-shelf solutions often fall short when dealing with materials that have unique flow characteristics or processing requirements.

Why Choose H&H Design & Manufacturing for Custom Screw Conveyors

At H&H Design & Manufacturing, we understand that many bulk material handling jobs don’t fit off‑the‑shelf equipment, especially when materials are sticky, cohesive, or need special flow/mixing behavior. Our strength lies in custom conveyor design, where we can engineer ribbon-style configurations for dry bulk lines.

H&H already offers a broad Conveyor portfolio under series names like Series 152, 153, 154, 150, 250, 151C, and 18.

Our conveyors are custom-manufacturable and modular, with scope for custom internal flighting or screw‑conveyor adaptations depending on your needs.

H&H emphasizes flexibility and custom solutions, ideal when standard conveyors are insufficient for sticky, cohesive, or challenging bulk materials.

By choosing H&H Design & Manufacturing, you gain access to custom screw conveyor systems for your unique material handling challenges.

Conclusion

Choosing the right ribbon screw conveyor flight type is critical for ensuring smooth, uninterrupted material flow, especially when handling sticky, viscous, or hygroscopic materials. Whether you need integral-leg, post-type, or double-flight ribbon configurations, the correct choice can prevent build-ups, reduce downtime, and improve operational efficiency.

At H&H Design & Manufacturing, we specialize in designing and manufacturing custom conveyors, including ribbon-style screw conveyors, tailored to your specific material handling requirements.

Contact us today for expert packaging solutions.

FAQ

What materials are ribbon flight screw conveyors made from?

Ribbon flight screw conveyors are available in mild steel, stainless steel, Monel, Inconel, Hastelloy, abrasion-resistant alloys, and nickel alloys, providing corrosion and wear resistance for demanding industrial applications.

What are the four types of conveyors?

The four main types of conveyors are belt conveyors, roller conveyors, screw conveyors, and chain conveyors. Each type is designed to handle specific material properties and movement needs.

What is the strongest type of screw?

The strongest type of screw is typically the shaftless screw conveyor. It is designed without a central shaft, allowing it to handle heavier, more abrasive materials.

What is a PID conveyor?

A PID conveyor refers to a conveyor system that is integrated with a PID controller (Proportional-Integral-Derivative). This system is used to precisely control the speed and operation of the conveyor.

What is the purpose of a screw conveyor?

The purpose of a screw conveyor is to transport bulk materials using a rotating helical screw inside a tube or trough. It provides continuous, controlled movement of materials.