Bagging chemicals is rarely simple. Fine powders cling to equipment, fluidize under vibration, and leak through weak seals. Hygroscopic materials cake or block flow. Granules surge and collapse, throwing off weight. When a 2,000 lb bag stalls and dust escapes mid-fill, cleaning piles up, operators lose time, and accuracy drops.

The bulk bag filler selection criteria for the chemicals industry start with material flow behavior. The filler must match powder or pellet characteristics with proper fill heads, inflation, dust control, and vibration. Accuracy comes next. It must hold stable weights at scale. Throughput matters too.

Each factor reduces exposure, prevents spillage, and stabilizes output. So how do you choose the system that fits your operation without trial and error? Let’s look at these criteria one by one and apply them to real equipment examples.

For Quick Readers: What You Should Not Miss

You choose the right filler only when you start with how each chemical actually flows, compacts, and creates dust in your plant.

The bulk bag filler selection criteria for the chemicals industry link directly to three outcomes you feel every day: waste, downtime, and safety.

Scale design, feed control, and settling features work together; if one is mismatched, you see drifting weights, rework, and customer complaints.

Frame adjustability, utilities, and automation are not add-ons; they decide whether your filler fits your real layout or constantly fights it.

Off-the-shelf machines rarely suit tricky chemistries or tight spaces, which is where engineered models and custom H&H Design & Manufacturing configurations close the gaps.

Why Bulk Bag Filler Selection Criteria for the Chemicals Industry Matter

Chemical materials rarely flow consistently. Powders aerate and form dust clouds, hygroscopic products absorb moisture and clump, and granules can surge or collapse during filling. If the filler design does not match how your material behaves, you lose weight consistency, face spills, and spend more time cleaning.

You need equipment that repeats the same result every cycle with proper scale capacity, weighing precision, and dust control to protect product, operators, and plant compliance.

Here are the core considerations you should account for:

Weight accuracy and consistency: A filler must control product flow so the final bag weight lands on target. Stable weighing systems prevent bounce at the end of the fill cycle and protect you from rejected bags.

Appropriate scale capacity: Choose scale systems sized for your batch range. Undersized scales drift and overshoot. Oversized scales respond slowly and reduce throughput.

Robust dust containment: Fill heads with seals, extraction ports, and controlled inflation protect operators. They also protect product purity, reduce residue buildup, and minimize cleaning tasks.

Selection criteria always vary by material behavior:

Material Type | Common Issues | Filler Requirements |

Fine powders | Aeration, airborne dust, inconsistent flow | Dust-tight heads, bag inflation, vibration, controlled feed |

Hygroscopic powders | Caking, bridging, clogging | Agitation, densification, stable seal, consistent feed rate |

Granules and pellets | Rapid discharge, surging, collapse | Fill stability, strong bag support, responsive scale |

The correct filler selection reduces downtime, helps you maintain clean operations, and keeps each bag within the required tolerance.

1. Material Flow Behavior

You cannot choose a filler without understanding how your material behaves under gravity. Powders may fluidize and behave like a liquid as air moves through them. Hygroscopic materials absorb moisture, pack tightly, and clog feed paths. Granules and pellets discharge fast, shift suddenly, and collapse unevenly in the bag. Each behavior shapes feeder selection, fill head design, and how you manage compaction.

Types of flow characteristics and their implications

Powders that fluidize or aerate: These materials move quickly, overshoot targets, and create airborne dust. You need a fill head with controlled airflow, bag inflation to stabilize the liner, and dust extraction at the seal. A vibration table supports compaction so trapped air escapes and the bag maintains its shape.

Hygroscopic chemicals that bridge or cake: Moisture causes these powders to form arches or dense lumps. A feeder with agitation or screw assist prevents blockage. The fill head should apply consistent pressure around the spout to maintain a sealed environment. Bag settling helps break compacted sections and keeps filling steady.

Granules and pellets with high mass flow but minimal dust: These materials discharge quickly and can overload the scale. A responsive scale system and stable bag support are essential. Fill heads may not need heavy extraction, but a controlled feeder and adjustable vibration protect against collapse.

Fine pigments with airborne dust risk: Even small volumes can contaminate equipment and nearby areas. You need dust-tight fill heads, inflatable seals, and an extraction port. A vibration table compacting short pulses prevents pigment pockets and stabilizes the center of mass.

2. Target Fill Range and Weight Accuracy Requirements

Chemical producers often work within ±1 lb per 1,000 lb because even small errors stack into lost product or rejected shipments. Your scale must match the bag size you run. Bags in the 2,000 to 4,000 lb range need stable load cells, controlled feed, and reduced flow near final weight to prevent overshoot.

Here are the practical factors you should account for:

Scale capacity matched to bag range: Choose a weighing system built for the 2k to 4k lb window. Undersized scales drift and overshoot, oversized scales respond slowly.

Dual-scale or dual-station setups for mixed materials: Staging one bag while filling another cuts idle time and keeps operators from overhandling heavy loops.

End-of-cycle weight control: Slow fill during the last 5 to 10 percent of target weight to avoid bounce, material overflow, and load-cell instability.

Inspection and tolerance discipline: Maintain calibration schedules and adjust feed parameters regularly. A plant running 30 bags per hour needs strict tolerance control, while low-speed, fine powder operations require tighter feed regulation and bag settling.

3. Bagging Throughput and Production Rate Expectations

Your expected bagging rate determines the type of filler you select. If your line runs fewer than 10 to 12 bags per hour, a manual or semi-automatic filler is often enough. Operators can hang loops, align the spout, and monitor weights without slowing production. Once you move into higher volume packaging, you cannot rely on manual intervention alone.

Here are the throughput thresholds you should consider:

Manual or semi-automatic systems for ≤10–12 bags/hr: These systems allow direct operator control, slower material feed, and less stress on the scale. They are suitable for small batch runs, specialty chemicals, or low-volume materials.

Electronic high-throughput fillers for 20–30+ bags/hr: Higher speeds require responsive scaling, automated feed control, and faster stabilization at the end of the fill cycle. Electronic bag fillers keep weights consistent during long shifts.

Conveyor and integration requirements: If you target continuous production, your filler must align with pallet conveyors or bag take-away systems. Integrating material handling prevents cycle delays and keeps the scale from re-zeroing between bags.

If fine powders, pigments, or cement keep coating your operators and equipment, the Series 110DS-P gives you sealed filling, pneumatic bag inflation, and reliable dust extraction.

4. Dust Control and Containment Systems

Chemical powders are not only messy. They can be reactive, hazardous to operators, and costly to clean once they contaminate nearby machinery. Dust escaping from the fill head increases exposure, creates slip risks, and leads to rejected bags. A filler must keep the product in the bag and the air around your operators clean.

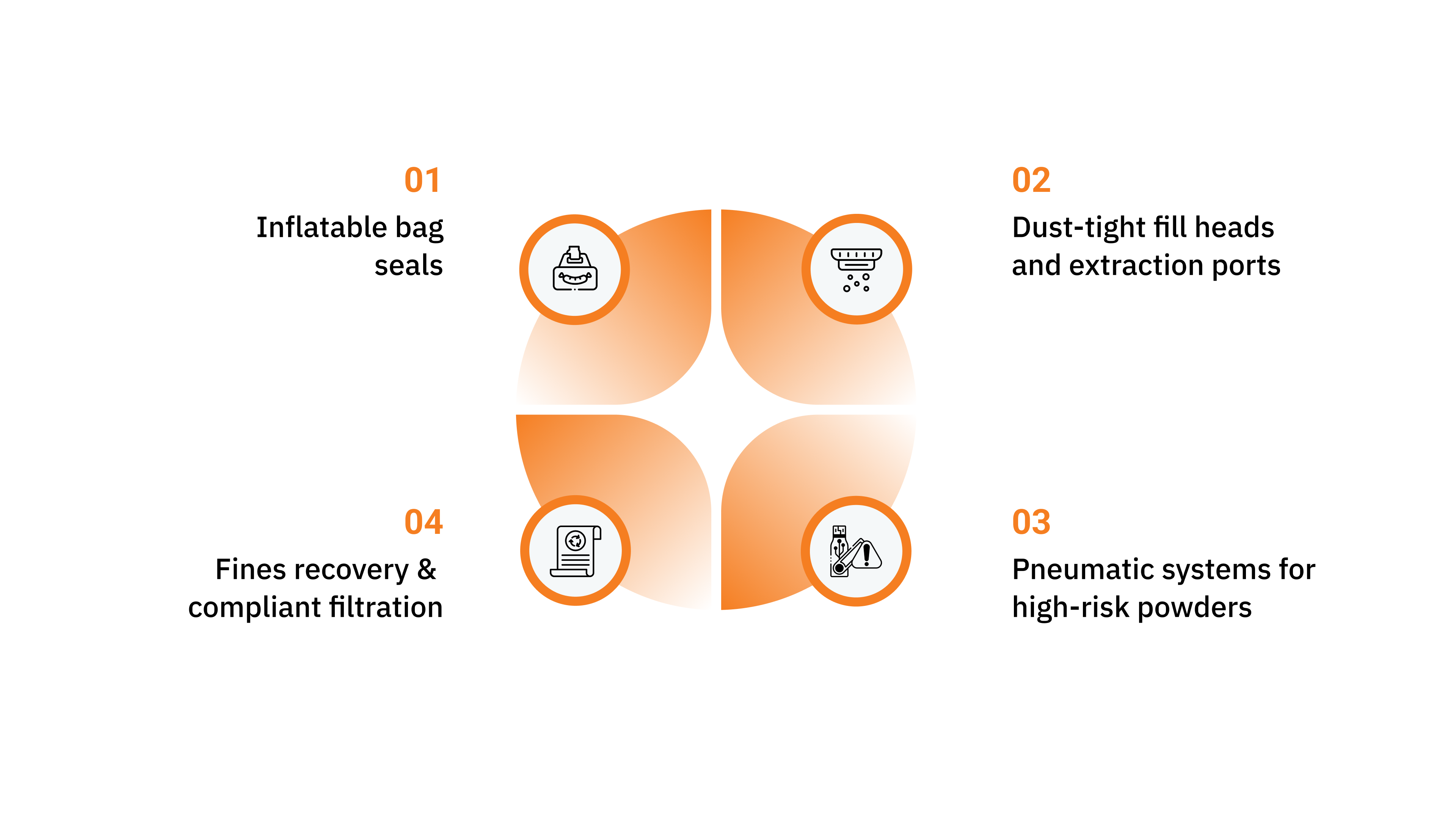

Key containment tools you should evaluate:

Inflatable bag seals: These seals expand against the inner liner, preventing air leaks at the fill spout. They reduce dust escape and stabilize airflow around the bag.

Dust-tight fill heads and extraction ports: A sealed fill head paired with active extraction removes airborne fines as the bag fills. This also lowers cleaning time and keeps scale sensors from being coated.

Pneumatic systems for high-risk powders: Pneumatic inflation and dust evacuation are essential for pigments, cementitious powders, and other fine materials. They maintain bag pressure and protect operators at the point of filling.

Fines recovery and compliant filtration: HEPA or central dust collection systems capture airborne particles and return usable product to the cycle. They support compliance and reduce loss during every fill session.

5. Frame Adjustability and Bag Size Compatibility

Chemical manufacturers often switch between different bag formats based on order size, product density, or shipping needs. A single fixed frame makes those changes slow, inaccurate, and stressful for operators. Adjustable equipment reduces strain and gives you consistency no matter the bag height or loop position.

Consider these structural features:

Pin and ladder adjustable frames: These systems let you set the bag height accurately, supporting multiple FIBC sizes without replacing hardware. Operators do not have to fight with straps or unstable bag positioning.

Quick-change adjustments: Mobile plants or short-run facilities need simple adjustments. When bag height or loop spacing can be modified in minutes, your filler stays productive between batches.

Filling stability and stress reduction: Adjustable frames prevent suspended bag stress, where weight shifts force the bag to lean or twist. Stable bag support ensures scale accuracy and reduces spillage during load transfer.

6. Utilities, Plant Integration, and Automation Readiness

Fill performance depends on how the machine fits your plant. Even well-designed systems fail when utility supply is inconsistent or when bag movement does not match conveyor timing. Integration must be considered before installation, not after.

Plan for these requirements:

Power supply: Many fillers operate on 115V or 3-phase systems. Choose the configuration that matches your production environment and avoids voltage drops under load.

Compressed air: Most fillers require 80 psi for bag inflation and dust control. Air supply should remain stable to prevent leaks, seal failure, or inconsistent inflation.

Material handling compatibility: If you use conveyors, pallet dispensers, vibration decks, or weigh decks, confirm that they interface with your filler. Poor integration forces manual labor and increases risks.

Automation and operator interface: PLC integration, simple HMIs, and saved fill profiles reduce training time. A familiar interface makes troubleshooting easier and helps you maintain throughput targets.

Increase throughput without risking accuracy. The Series 330E from H&H Design & Manufacturing integrates automation, conveyors, and bag settling so your line keeps moving.

7. Material Settling, Vibration, and Bag Stability

Chemicals often trap air as they enter the bag. Without compaction, the bag may hold less material than expected, shift during transport, or collapse on the pallet. Settling is not cosmetic. It is a core requirement for maintaining density and predictable weight.

Use the following tools to control stability:

Vibration tables or densification cycles: Short pulse vibration pushes trapped air upward and allows heavier particles to settle. The bag becomes denser and more secure on the pallet.

Controlled agitation: Bags that settle evenly maintain structure. They do not bulge in corners or slump once moved by a forklift.

Transport and palletization impact: Densified bags withstand stacking, movement, and shipping better. Your load remains consistent when it reaches the customer or downstream process.

8. Operator Safety and Ergonomics

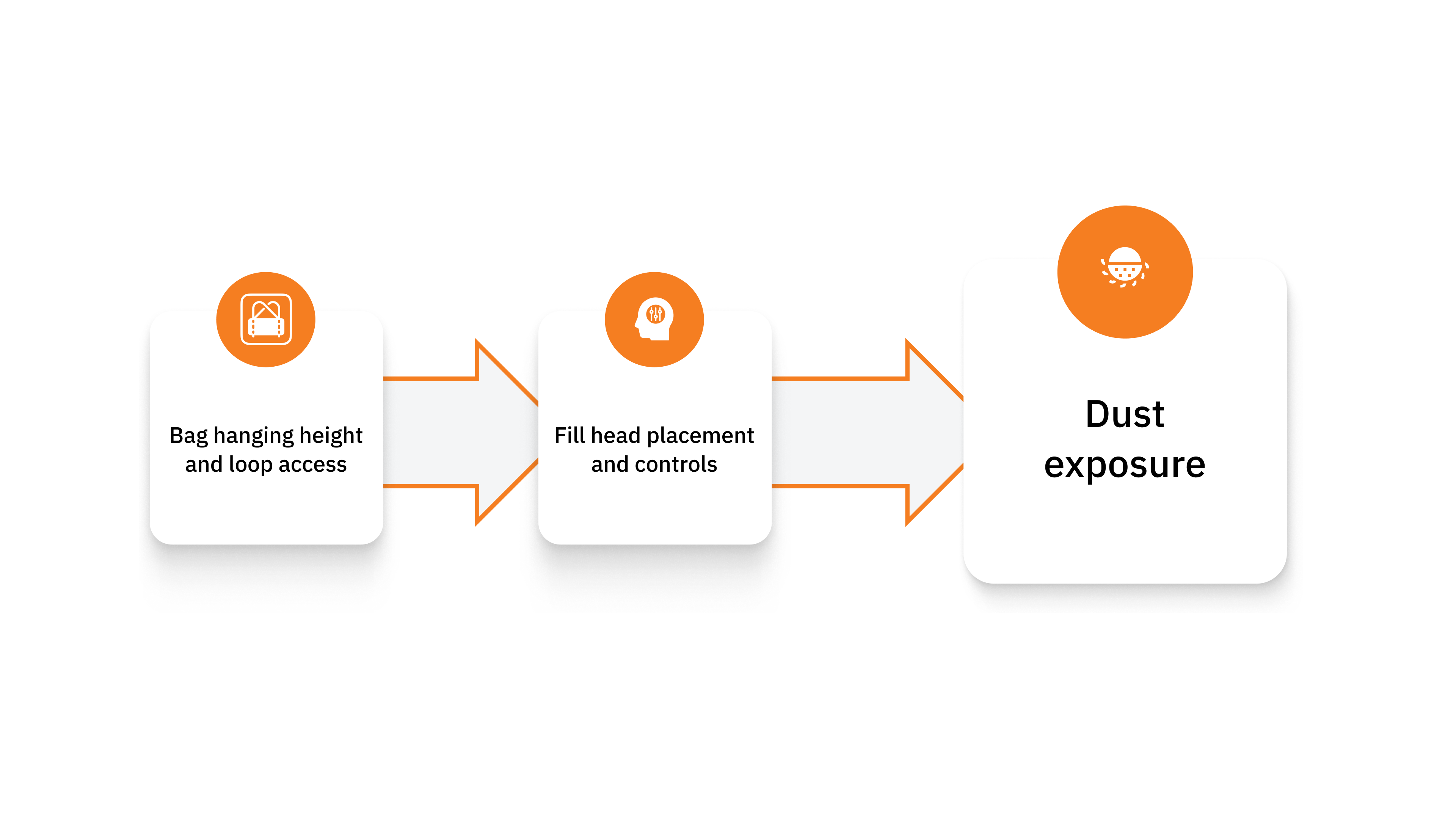

Poor ergonomics increase fatigue, mistakes, and exposure to airborne chemicals. A filler must not force operators into awkward or unsafe positions. The system should manage the heavy lifting and keep human contact minimal.

Here are the priority elements to evaluate:

Bag hanging height and loop access: Operators must not stretch, lean, or climb to attach loops. A stable lift mechanism or assist system preserves safety and speed

Fill head placement and controls: A head that locks in place, supports inflation, and keeps emergency stops in reach reduces accidents. Operators should control airflow without putting their face near the spout.

Dust exposure: Sealing and extraction remove airborne particles before they reach the operator. Less dust means fewer respiratory issues and reduced PPE dependency.

9. Maintenance, Serviceability, and OEM Support

A filler that is difficult to maintain will consume labor, create frequent stops, and increase long-term costs. Maintenance should be straightforward and repeatable, not a guessing game.

Focus on these service elements:

Modular components and accessible wear parts: Common wear zones, such as seals, spouts, and load cells, must be reachable without disassembly. Clear access shortens maintenance windows.

Diagnostics and fault indicators: PLC data, scale feedback, and alarm signals help you isolate issues quickly. Operators do not have to troubleshoot blindly.

Spare parts and service response: Reliable OEM support prevents extended downtime. You should be able to source seals, valves, and scales without lengthy lead times.

Calibration discipline: Routine calibration maintains accuracy across bag types and material densities. It also prevents drift that accumulates into costly overfill.

For continuous-duty packaging where every shift counts, the Series 2000 delivers stable weighing and industrial-grade reliability. Contact H&H Design & Manufacturing to configure it for your production line.

Most plants fit into these criteria just fine until the material says otherwise. When your layout, bag design, or flow behavior refuses to cooperate, you are no longer choosing a filler, you are engineering one.

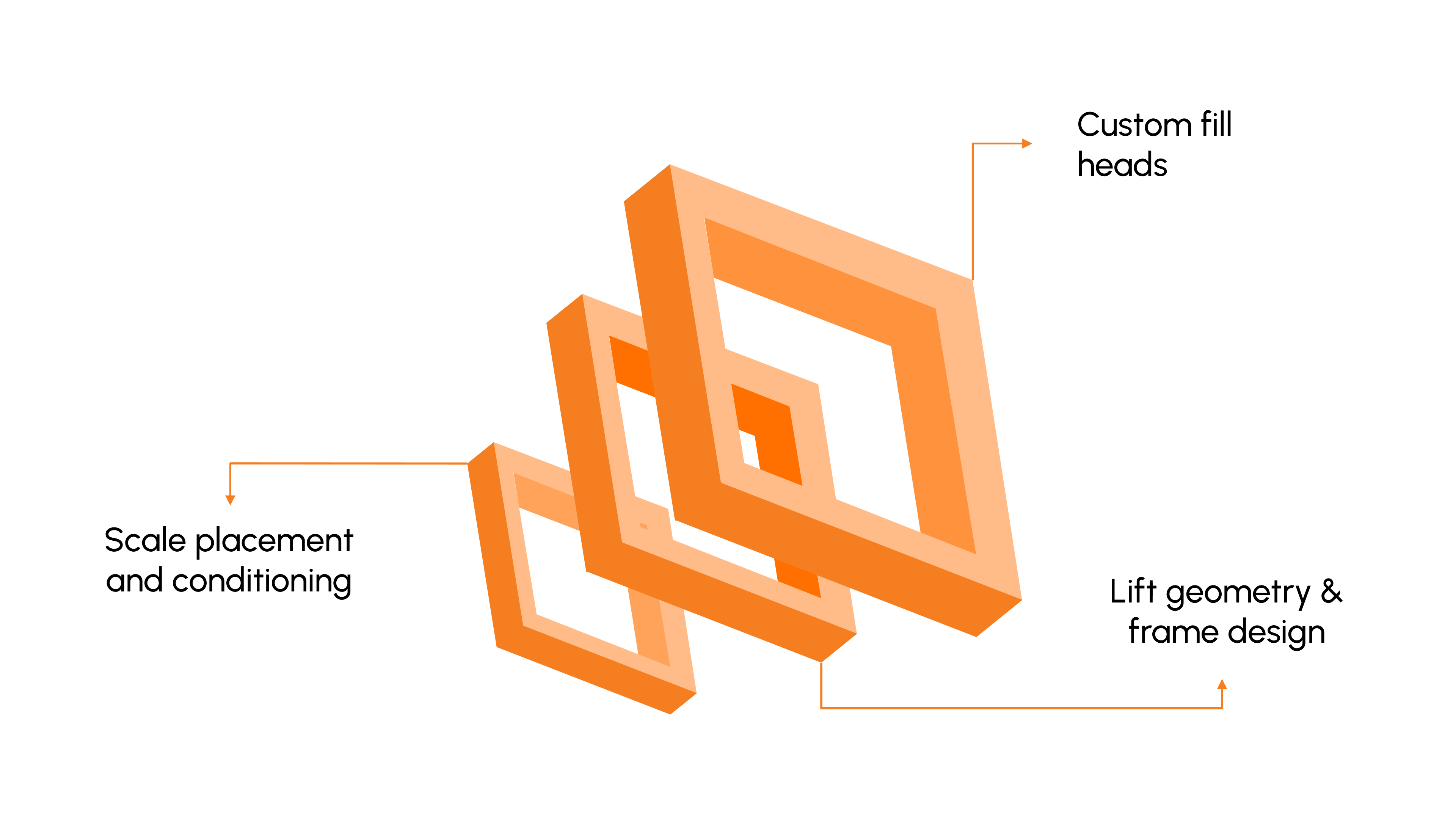

When to Consider a Custom Bulk Bag Filling System

Chemical plants rarely fit a standard layout. You may have restricted bays, low ceiling clearance, or conveyor systems that were installed years before bulk fillers were added. Some materials demand controlled airflow at the spout, while others need conditioning or vibration before the bag stabilizes. In these cases, a standard filler will force you to adapt your process around the machine instead of the machine supporting your process.

Custom systems address specific constraints:

Custom fill heads: For powders that leak, fluidize, or generate dust, you may need inflatable seals, integrated extraction, or unique spout geometry to maintain containment.

Lift geometry and frame design: Plants with tight aisles or variable bag heights benefit from motorized lifts, reinforced frames, or compact structures that align with existing material flow.

Scale placement and conditioning: Dual-deck scales, off-center weigh cells, or densification cycles create stability during weighing and transport when standard layouts cannot handle material behavior.

Custom engineering is not a luxury. It is a solution when your material, space, or legacy equipment introduces challenges that no off-the-shelf filler can handle. When the constraints pile up, guessing is expensive. This is where H&H Design & Manufacturing steps in and designs around your material, not around a catalog.

How H&H Design & Manufacturing Helps You Choose the Right Bulk Bag Filler

AT H&H Design & Manufacturing, we approach bulk bag filling as a process problem, not a catalog choice. When you tell us what chemical you are running, how it flows, your target bag rate, and the dust sensitivity in your plant, we match that reality to the right equipment.

Every model we build or recommend has already been proven in facilities with similar bag weights, operators, and throughput expectations. Our job is not to sell you the biggest filler. It is to make sure the one you install works every day without struggle.

Our Bulk Bag Fillers Designed for Chemical Applications

Model | Working Range & Throughput | Best Material Types | Where It Performs Best |

Series 110DS | 100–4,400 lb, 10–25 bags/hr, ±1 lb per 1,000 lb | Powders, granules, ingredients, bulk chemicals | Plants with multiple bag sizes that need precise scale performance and stable filling |

Series 110DS-P | 100–4,400 lb, 10–25 bags/hr, ±1 lb per 1,000 lb | Fine powders, pigments, cement, starch | Facilities where airborne dust is a constant risk and containment must be consistent |

Series 330E | 100–4,400 lb, 20–30 bags/hr, ±1 lb per 1,000 lb | Minerals, plastics, high-volume chemicals | Lines with conveyors, pallet dispensers, and rapid turn cycles |

Series 2000 | Up to ~4,400–6,000 lb, >30 bags/hr | Fertilizer, cement, mining chemicals | Continuous-duty packaging environments with automation and heavy loads |

We design these machines to handle the realities of chemical packaging: dust control, accurate weights, stable bag frames, and utilities that do not fail mid-shift. If none of these models fit your environment, we engineer custom systems that do. Look through our full range of bulk bag systems to find the model that fits your operation.

Conclusion

Selecting a bulk bag filler is not about finding the largest machine or the fastest unit. Your decision should be based on how your chemicals flow, how tightly you need to control weight, the level of dust containment required, and whether your frame supports every bag size you run. Utilities, operator safety, throughput expectations, and long-term serviceability all shape how well the filler performs once it is installed.

The wrong system increases spillage, forces unnecessary cleaning, and creates safety risks. The right one provides consistent bag weights, stable operation, and a process that lasts for years without constant adjustments. What material in your facility causes the most waste or dust? Do you need dust-tight filling or a frame that adapts to different bag formats?

If you want guidance grounded in field experience, talk to our team. We design, build, and commission the equipment ourselves, so you receive a filler that matches your process rather than a catalog description.

FAQs

Q: How do I determine if my filler is oversized for my chemical packaging line?

A: Oversized fillers create slow response during filling which lowers system responsiveness and forces longer fill cycles. You will also notice overfeed at startup, inconsistent settling, and longer stabilization times compared to your current output.

Q: What signs indicate that my current bulk bag filler is damaging the bag liner?

A: Look for liner tearing around the neck, uneven tension on loops, or wrinkles forming at the base after filling. These symptoms suggest excessive force during loading or poor alignment between the spout and the bag body.

Q: Can a filler cause product separation during packaging if my chemical blend contains multiple particle sizes?

A: Yes, unstable feed speed or uneven bag vibration can stratify the mixture during filling. The top layer becomes lighter and the bottom heavier, which affects uniformity and downstream handling.

Q: How do I prevent static buildup when bagging dry chemical powders that cling to equipment?

A: Use static-dissipative bag liners and grounding points on the filler frame to discharge accumulated charge. Avoid high-velocity airflow near the spout because it increases particle adhesion and dust carryover.

Q: Does filler orientation matter when installing equipment near existing conveyors or mixers?

A: Orientation affects load transfer, fork access, and sensor accuracy. A poor layout forces extra handling steps and disrupts the rhythm between upstream feed and downstream palletization.

Q: What maintenance indicator should trigger bag filler recalibration in a chemical plant?

A: Any deviation between reported bag weight and verified pallet weight signals sensor drift. If this gap repeats across several batches, recalibration should be performed immediately to avoid systematic loss.