Handling bulk bags safely is more than just a compliance issue; it’s a critical factor in preventing workplace accidents, reducing downtime, and ensuring product quality. According to the Occupational Safety and Health Administration (OSHA), 5,283 fatal workplace injuries related to improper handling of materials occur annually in the U.S. alone.

The challenge is significant in industries like food processing, chemicals, and agriculture, where improperly filled or discharged bulk bags can lead to serious accidents, equipment failure, or even contamination. But these risks don’t have to be inevitable.

By implementing well-defined safety guidelines for filling and emptying bulk bags, businesses can reduce the chance of injury, improve operational efficiency, and maintain compliance with industry standards.

In this article, we’ll walk you through the safety practices that will keep your team safe, your equipment intact, and your processes running smoothly.

Key Takeaways

Inspect Bags and Equipment: Always check bulk bags and handling equipment for damage, ensuring they are rated for the Safe Working Load (SWL) and free from defects to prevent failures and injuries.

Distribute Material Evenly: Fill bags evenly and avoid overfilling to maintain stability. Use stabilizing frames if necessary to prevent bulging or instability during lifting.

Use Proper Lifting Techniques: Ensure all lift loops are used and kept vertical. Never exceed load limits or use improper lifting methods to avoid bag failure or accidents.

Control Dust and Static: Implement dust suppression and grounding systems when handling powders or flammable materials to prevent hazards like contamination or static discharge.

Store and Transport Bags Safely: Keep bags in dry, covered areas off the ground, and stack them properly to avoid damage. Ensure safe transport methods to protect the bags during movement.

Understanding Bulk Bags & Their Classifications

Bulk bags, also known as Flexible Intermediate Bulk Containers (FIBCs), are large, flexible containers used to transport and store dry, bulk materials such as powders, grains, chemicals, and fertilizers. Understanding the different types of bulk bags and their classifications helps in safe handling practices and preventing accidents.

Type A: These bags are designed for non-conductive materials and do not provide protection from static charges.

Type B: Type B bags are designed for materials that might generate static charges but are not hazardous enough to require grounding.

Type C: These bags are conductive and are designed to safely handle combustible materials.

Type D: Type D bulk bags are similar to Type C in that they are conductive, but, unlike Type C bags, they do not require grounding.

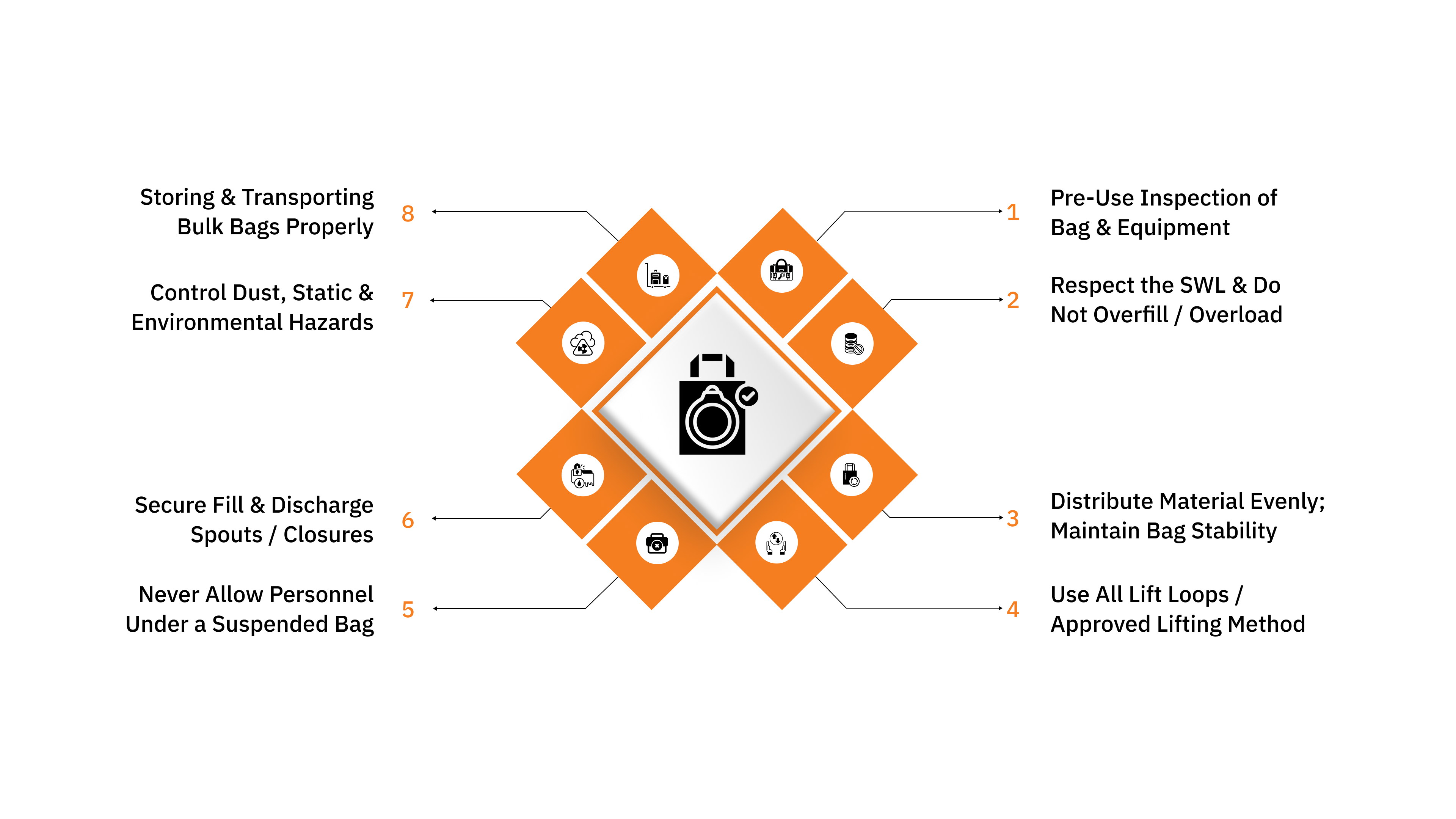

Top 8 Safety Guidelines for Filling and Emptying Bulk Bags

When handling FIBC (Flexible Intermediate Bulk Container) bags for filling and emptying, it's essential to follow specific precautions to ensure safety and protect both the bag and its contents. Here are the key safety guidelines to keep in mind during this process.

Pre-Use Inspection of Bag & Equipment

Inspect both the bulk bags and the equipment used for handling them to ensure they are in safe, operational condition before use. A small tear in the bag, a broken loop, or a defective lifting mechanism can lead to product spillage, equipment damage, and workplace injuries.

This step is crucial in high-risk industries like food processing, chemicals, mining, and agriculture, where any mishap can cause not only physical harm but also regulatory violations.

Key Guidelines

Inspect bulk bags for tears, damage, and integrity (seams, loops, spouts).

Check lifting equipment (crane hooks, forklift tines) for sharp edges or wear.

Check if the sealing mechanisms are intact and functional.

Examine conveyors and discharge systems for blockages or defects.

The weight capacity of lifting equipment should match the bag’s Safe Working Load (SWL).

Respect the Safe Working Load (SWL) & Do Not Overfill / Overload

Every bulk bag has a Safe Working Load (SWL), which represents the maximum weight the bag can safely hold. Exceeding this weight can cause the bag to rupture, resulting in spills, material loss, or even injuries. Overfilling can distort the bag, making it more difficult to handle or discharge safely.

This guideline is especially crucial for automated bag handling systems, where weight calibration and load distribution are key to maintaining safety and efficiency.

Key Guidelines

Always check the bag’s SWL before filling.

Use a calibrated scale for accurate weight measurements.

Avoid overfilling the bag, even if it seems to fit.

The lifting equipment must be rated for the SWL.

Regularly inspect equipment for any signs of wear that could impact load-bearing capacity.

Distribute Material Evenly; Maintain Bag Stability

When filling bulk bags, even material distribution is essential for maintaining bag stability during lifting and transport. Uneven distribution can lead to bulging, which can cause the bag to become unstable, leading to equipment failure and product spillage.

Key Guidelines

Fill bags slowly and evenly to maintain balance.

Avoid filling to capacity too quickly to allow the material to settle properly.

Check the bag’s alignment and ensure it’s not leaning or bulging.

Use stabilizing frames or systems so that the bag stays upright.

Inspect the bag regularly for signs of deformation before lifting.

Use All Lift Loops / Approved Lifting Method; Keep Loops Vertical

When lifting a bulk bag, it's critical to use all the loops provided and keep them vertical during the lift. Lifting with only one loop or using incorrect methods can cause the bag to rip or tear, leading to product loss, injuries, or damage to the equipment.

For heavy-duty lifting, spreader bars or lifting frames should be used to distribute the weight evenly and protect the integrity of the bag and equipment.

Key Guidelines

Use all the loops provided for lifting the bulk bag.

The loops must be vertical when lifting, and never angle them.

Inspect loops before lifting so that they’re intact.

Use spreader bars or lifting frames for heavier bags to distribute weight evenly.

Never exceed the rated load capacity when lifting.

Starting small or scaling up gradually? H&H Design's Series 35 / entry‑level bulk bag fillers offer a cost‑effective way to adopt best‑practice safety procedures and minimize manual handling risk — perfect for lower throughput or pilot operations

Never Allow Personnel Under a Suspended or Unsupported Bag

Prevent human exposure to risk when a filled bulk bag is suspended, in case of bag failure, loop breakage, equipment malfunction, or accidental drop.

According to published safe‑handling guidance for FIBCs, “Never allow personnel to stand or place any appendage under a suspended FIBC.” Suspended bags carry significant weight. If a loop fails, a hook slips, or lifting equipment fails, the entire bag can drop. That poses serious injury, or worse, to anyone underneath.

Key Guidelines

Never allow any person to stand, walk, or place body parts under a suspended or raised bulk bag.

Use lifting devices rated for the load and that keep bags stable, and avoid jerky lifts or sudden stops.

Make sure the lifting equipment (hooks, forklift tines, spreader bars) is properly maintained and free from defects.

Always lower the bag completely and detach the load before personnel approach or perform any task beneath.

Secure Fill & Discharge Spouts / Closures; Use Liners When Required

Properly sealing both the fill and discharge spouts of bulk bags is crucial for avoiding spills, dust contamination, and loss of material during the handling process. If using liners, these must be fitted correctly to prevent leakage or contamination, especially when handling sensitive or hazardous materials.

By adhering to these practices, you ensure the safety of your team and work environment, but also protect the integrity of the product and avoid unwanted material wastage or contamination.

Key Guidelines

After filling, close and secure the top fill spout or duffle as per the manufacturer’s instructions.

If the bag has a discharge spout or bottom outlet, it should be closed or tied off until you are ready for discharge.

Avoid cutting spouts or rushing discharge. Open spouts gently and in a controlled environment to minimize dust or spills.

Make sure the discharge area is equipped with dust‑containment or ventilation solutions when handling fine powders or hazardous materials.

Control Dust, Static & Environmental Hazards (for Powders, Flammables, Sensitive Materials)

When handling certain types of materials, such as powders, flammables, or sensitive chemicals, controlling environmental hazards is critical. Dust suppression systems should be implemented to reduce airborne particles and prevent respiratory hazards or product contamination.

Key Guidelines

Implement dust suppression systems (e.g., dust collectors, enclosed filling areas) when filling or emptying dusty materials.

Proper grounding of Type C or D bags to prevent static discharge when handling flammable materials.

Maintain a clean, dry, and well-ventilated environment to reduce moisture and contaminants that could affect product quality.

Use static-free equipment when handling combustible materials to reduce ignition risk.

Wear PPE (e.g., respirators, gloves, eye protection) when handling powders or chemicals.

Storing & Transporting Bulk Bags Properly: Protect from Moisture, UV, Damage; Stack Safely

The bulk bags must be stored and transported in a way that protects their durability, especially when they are not in use or during transit. Improper transportation can compromise bag strength, introduce contaminants, or weaken material integrity. Bulk bags exposed to moisture, UV rays, or sharp objects may degrade, causing them to tear or break during subsequent handling. Correct storage and stacking are necessary to avoid damage to the bags and prevent hazardous conditions during transportation.

Key Guidelines

Store bags in a dry, covered area to protect them from exposure to moisture, UV rays, and extreme temperatures.

Keep bags off the ground to avoid contact with dirt or moisture, and use pallets when necessary.

Stack bags properly to avoid crushing or shifting; never stack bags too high or unevenly.

When storing multiple bags, use proper stacking methods (such as pyramid stacking) for stability and avoid crushing or damaging the bags.

Why H&H Design & Manufacturing is the Right Partner for Safe Bulk‑Bag Handling

H&H Design & Manufacturing offers a wide range of equipment, from small bag fillers and conveyors to industrial‑grade bulk‑bag fillers and unloaders, covering weights from as little as 2 oz up to 3,000+ lbs.

Bulk‑Bag Fillers (e.g. Series 110DS, 330E): Heavy‑duty machines with industry-grade fillers, adjustable bag frames, digital weighing, dust‑tight inflatable fill heads, and support for large FIBCs.

Bulk‑Bag Unloaders & Handling Systems: For safe discharge of materials from FIBCs, minimizing manual handling, reducing risk of bag rupture, dust exposure, or instability during emptying.

Conveyors and Integrated Lines: Seamless conveyors and line‑integration systems to transport filled or empty bags, reducing the need for manual lifting/handling.

Flexible / Custom‑Engineered Solutions: Customize equipment, bag frame size adjustments, dust‑tight fill heads, and integration with plant control systems. All these are ideal for customers processing powders or chemicals that require strict safety and hygiene compliance.

With H&H Design & Manufacturing’s comprehensive range of equipment, you can streamline your powder handling and reduce manual intervention.

Conclusion

Safety is paramount when filling and emptying bulk bags, as improper handling can lead to accidents, product loss, and equipment damage. By following key safety guidelines, manufacturers can reduce the risk of injuries, boost operational efficiency, and maintain product integrity. Investing in reliable, purpose-built equipment is crucial to supporting these safety practices.

H&H Design & Manufacturing provides customized solutions designed to enhance safety and optimize bulk bag handling operations. Ready to take your bulk bag handling to the next level?

Contact H&H Design & Manufacturing today for expert packaging solutions.

FAQs

How to unload a bulk bag?

To unload a bulk bag, ensure it’s properly supported using a forklift, crane, or unloader system. Secure the discharge spout, open it gently, and allow the material to flow smoothly while ensuring stability to avoid spills or bag damage.

Are Bulk bags reusable?

Yes, bulk bags can often be reused depending on their condition and the material they’ve carried. After each use, inspect for damage like tears, worn loops, or compromised seams to determine if it’s safe for reuse.

What is the maximum weight of a bulk bag?

The maximum weight of a bulk bag, known as its Safe Working Load (SWL), typically ranges from 2,000 lbs to 4,400 lbs, depending on the bag's design and material. Always check the SWL label to ensure it aligns with your load requirements.

What are the 7 S of safety?

The 7 S of safety are: Sort, Set in Order, Shine, Standardize, Sustain, Safety, and Support. These principles focus on organizing the workplace for safety, efficiency, and continuous improvement.

What is SWL in jumbo bags?

SWL (Safe Working Load) in jumbo bags refers to the maximum weight the bag can safely handle during use. It’s essential to always respect the SWL to avoid bag failure, spills, or accidents during lifting and transport.